- Production Machines

- Other Manufacturing Equipment

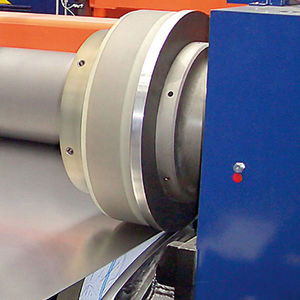

- Automatic flanging machine

- HEINRICH GEORG GmbH

Automatic edge-trimming machine doublefor sheet metal

Add to favorites

Compare this product

Characteristics

- Type

- automatic, double

- Treated product

- for sheet metal

Description

For the processing of carbon steel, silicon steel, stainless steel and non ferrous metals such as aluminium and alloys, lithographic, copper, brass and titanium.

The most essential parameters

- Strip widths up to 2,800 mm, dependent on material and customers demands

- For line speeds > 1,800 m/min, dependent on material properties and customers demands

- Edge-trimming of typical gauge ranges of: 0.08–0.8 mm, 0.1–1 mm, 0.3–4.0 mm, 0.5–6 mm, 1–8 mm, 2–10 mm, 4–15 mm

- Highest cutting tolerances

- Perfect cutting quality with low burr on the cutting edges

- Single head edge-trimming shears for finishing lines

- Double head edge-trimming shears for process lines

- Edge-trimming shears in double eccentric and spindle adjustment design

- Centre cut shears

- Automatic adjustment of width, cutting gap, and knive overlap

- Regrinding of the knives on the circumference or on the flat surface

- Permanent driven shear heads or non driven with free run clutch

Catalogs

No catalogs are available for this product.

See all of HEINRICH GEORG GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.