- Machine-tools

- Machine Tool Accessory

- Spring clamp

- HEINRICH KIPP WERK GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

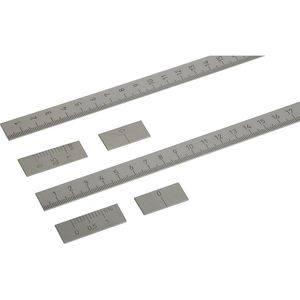

Spring clamp K1500 series

Add to favorites

Compare this product

Characteristics

- Type

- spring

Description

With this patented clamping system, two components can be positioned without tools via form fit and then clamped together by frictional connection. The clamping range and the holding force is adjustable.

Material:

Handles, cast aluminium, EN AC-46200.

Thrust washer, fibreglass reinforced PA 66 GF 35 X plastic.

Hinge pin stainless steel.

Tie rod, washer, collet, disc spring, steel.Version:Grips fine structure powder-coated, black or red RAL 3003.

Thrust washer, black.

Washer blue passivated.

Tie rod and collet black oxidised.Note:It is recommended that the cam lever is in a vertical position when the collet is positioned in the bore.

The function of the clamping system was tested in bores with tolerance H7. All values for retaining force are guide values and are given without safety factor.

The suitability for the respective application must be checked by the user.Advantages:Two components can be joined together without tools. The components are perfectly centred in the clamped state. The compact design means that the mandrel collet with cam lever can even be used in blind holes. There are no specific dimensional requirements for the holes. Additionally, the surfaces and design do not need to have any specific properties.Functional principle:The clamping system is inserted in the hole in the open state. At the beginning of the locking process, the mandrel collet expands and clamps itself in the lower component. The integrated disc spring assembly creates a positive down force that also clamps the two components to one another at the end of the locking process.Drawing reference:

1) actuated

2) not actuated

Catalogs

No catalogs are available for this product.

See all of HEINRICH KIPP WERK GmbH & Co. KG‘s catalogsOther HEINRICH KIPP WERK GmbH & Co. KG products

Operating parts | standard elements

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.