Compression spring wiremetalsteel

Add to favorites

Compare this product

Characteristics

- Function

- compression

- Type

- wire

- Material

- metal, steel

- Applications

- construction, heating, valves, coil

Description

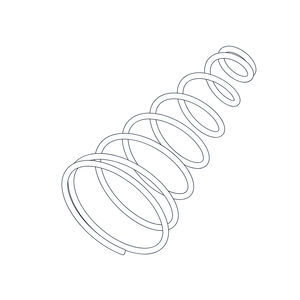

Hot Wound Springs

For more than 70 years, MW has been producing hot wound springs (also known as hot coil springs, hot compression springs, or hot helical springs) and related products. Our commitment to quality, technology, process improvement and our customers, has made us a premier supplier within the manufacturing industry. We have the ability to control metallurgical processes and guarantee part quality to our customers, earning us a TS 16949 certification, among others. This guarantees the best delivery and the most competitive pricing in the industry.

Hot Wound Springs Overview

Characteristics

Hot wound springs are produced by heating the metal (generally steel), forming it into the desired shape, and tempering it to the preferred specifications. Hot wound springs are preferred when larger steel springs are needed since steel in its natural state is difficult to form in larger applications without cracking.

Application & Industries

Hot wound springs are generally found in larger applications like vehicle suspensions, valve actuators, and in large trucks and outdoor equipment. They are used in several industries, some of which include, agriculture, automotive, construction, military, petrochemical, valves, and mining.

Catalogs

No catalogs are available for this product.

See all of HELICAL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.