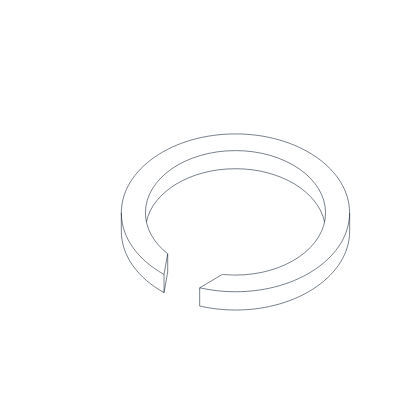

External snap ring

Add to favorites

Compare this product

Characteristics

- Options

- external

Description

Snap Rings & Retaining Rings

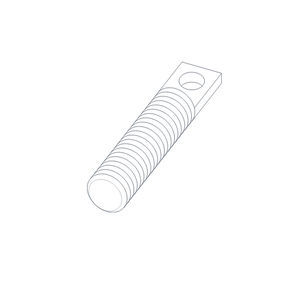

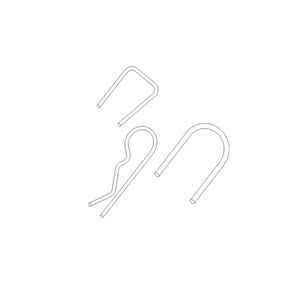

MW Components manufactures custom precision-engineered retaining rings, also known as coiled rings, snap rings, round wire rings, circlips, square section rings, rectangular section rings, custom-shaped sections rings, or tapered section rings. Our snap rings are available in various end configurations for use in multiple applications.

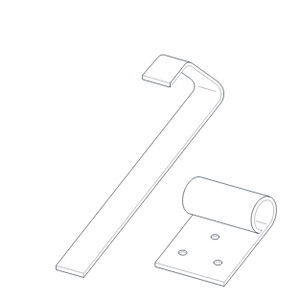

There are two main types of snap rings—internal rings, which are assembled inside a cylinder where the ring fits inside a hole (or bore), and external rings, which are assembled on the outside of the shaft.

Characteristics of Snap Rings

Retaining rings are designed for use on shafts or in bores. The ring is installed into a groove, thereby creating a shoulder to accurately position and retain other assembly components. The retaining shoulder is created when the ring attaches itself to the bore or shaft, typically by snapping into a groove.

Retaining Rings vs. Traditional Fasteners

The advantages of using retaining rings include their ease of assembly, low manufacturing cost, and positioning accuracy compared to traditional fasteners. Retaining rings only require a groove. This advantage over traditional fasteners requires threaded components, mating threaded holes, access holes, and counter-bores. Retaining rings function with a minimal amount of surface preparation to either the shaft or the housing.

Catalogs

No catalogs are available for this product.

See all of HELICAL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.