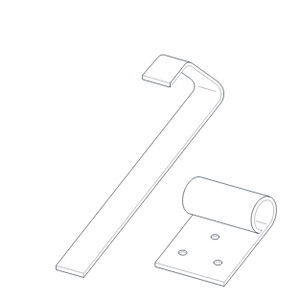

Wire form

Add to favorites

Compare this product

Description

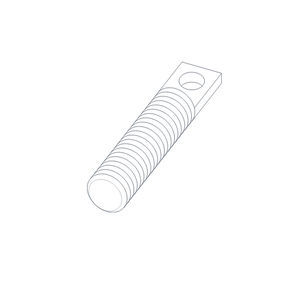

Shaped wire (usually spring steel) is used to create wire forms, which have various uses and are often seen in products that we use every day. Some examples include lightbulb filaments, musical instruments, clocks, medical trays, pins, pegs, and rivets.

Shaped wire is finished and then bent or formed using external pressure generally by using four slide technology or a punch press. Possible configuration opportunities are endless, allowing for multiple customization options, which allows this product to be quite diverse in its use cases.

Custom wire forms are manufactured in a variety of shapes to perform specific functions. There are a variety of customizations that can be performed with wire forms, so we will work with you to determine the best material, sizing, and manufacturing process to suit your needs.

Custom Wire Forms

MW Components produces custom wire forms in a wide variety of wire sizes from .006″ through 1.00″ and in lengths up to 36″. We produce a number of wire-formed products including several styles of pins like cotter pins, hitch pins, and lock pins, as well as S hooks, D rings, figure 8 hooks, grip clips, hog rings, and others.

In addition to our large variety of configurations and sizes, many material options are available depending on your design needs and application requirements – including high-strength and annealed spring materials. We offer prototyping and various coatings or surface treatments including, plating, passivation, cleaning, polishing, and heat treatments, in addition to custom packaging and JIT (Just In Time) delivery as needed.

Catalogs

No catalogs are available for this product.

See all of HELICAL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.