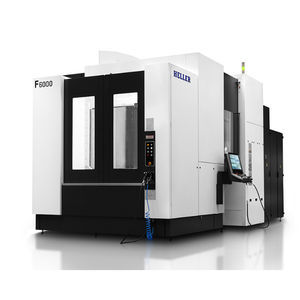

4-axis CNC machining center H seriesverticalwith rotary tableHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- vertical

- Structure

- with rotary table

- Spindle mount

- HSK A-63, HSK-A 100

- Associated functions

- cutting

- Applications

- for heavy loads

- Other characteristics

- high-performance, high-productivity, high-power, with pallet changer

- X travel

Max.: 2,400 mm

(94.49 in)Min.: 630 mm

(24.8 in)- Y travel

Min.: 630 mm

(24.8 in)Max.: 1,600 mm

(62.99 in)- Z travel

Min.: 630 mm

(24.8 in)Max.: 1,600 mm

(62.99 in)- Work feed X-axis

41 m/min, 65 m/min, 80 m/min, 90 m/min

- Work feed Y-axis

45 m/min, 65 m/min, 80 m/min, 90 m/min

- Work feed Z-axis

45 m/min, 72 m/min, 80 m/min, 90 m/min

- Table load capacity

Min.: 800 kg

(1,764 lb)Max.: 8,000 kg

(17,637 lb)- Positioning accuracy

0.005 mm, 0.008 mm

(0.0002 in, 0.00031 in)- Tool-changing time

Min.: 2.2 s

Max.: 6.7 s

Description

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centres. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes – even at their limits, seven days a week in 3-shift operations.

Key facts

designed for high process stability and highly resilient up to limits

high availability and longevity thanks to robust, reliable technology

24/7 series production, stand-alone or integrated in flexible manufacturing systems

short chip-to-chip times thanks to quick tool changer and high axis dynamic

horizontal spindle for optimum chip fall

easy to automate with workpiece or pallet automation

highly standardised and individually configurable

can be used for any range of large parts and materials

ideal solution for series production of small to medium batch sizes

broad range of sizes suitable for almost any workpiece

Machine concept

The rigid design and topology-optimised structural components are the basis from which our H-series 4-axis machining centres achieve their high cutting performance and accuracy. You can also rely on top quality – with high productivity.

Basic structure

Crossbed and travelling column in gate design

high stability and damping in the force flow through topology-optimised structural components in cast iron

thermo-symmetrical design and optimised flow of forces

a broad selection of robustly designed machining units

a broad selection of tool magazine types: chain or rack

VIDEO

Catalogs

4-axis machining centres H

28 Pages

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- Drilling CNC machining center

- Machining center for the automobile industry

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

- 4-axis CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.