Crankshaft CNC machining center R series3-axisvertical2-spindle

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Number of spindles

- 2-spindle, 3-spindle

- Associated functions

- milling, cutting, drilling

- Applications

- for the automobile industry, for crankshafts

- Power

Max.: 48 kW

(65.26 hp)Min.: 22 kW

(29.91 hp)

Description

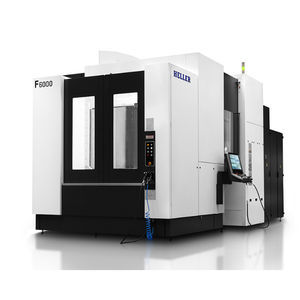

As a system supplier to the automotive industry, HELLER develops manufacturing solutions for the flexible complete machining of crankshafts and camshafts. We are one of the few suppliers worldwide that has extensive experience across the entire process chain. The HELLER RFK/DRZ/MCC 15/RFN production systems and various machining centres offer the core processes for pre-machining crankshafts and camshafts. These efficient custom machines can be equipped as a stand-alone solution or as interlinked individual machines within a manufacturing system.

Key facts

comprehensive HELLER expertise across the entire process chain

customised process engineering matched to the requirements concerned

responsible overall project management

highly productive complete solutions using: external or internal milling, turn-chasing, milling, drilling and thread cutting

use of other technologies, or also in combination

External milling of crankshafts

External milling is a flexible and productive method used primarily in the mass production of small to medium-sized crankshafts. The RFK crankshaft production systems from HELLER are for machining concentric and eccentric bearing points, cheek faces and cheek outer diameters as well as special contours in a highly productive manner – often in just one set-up.

tool generates the cutting speed

workpiece generates the feed rate

use of external cutters

cutter diameter can also be used for most hollow cam profiles.

tool profile is designed according to the profile to be milled

for the machining of crankpins, 2 interpolating NC axes are used which are positioned eccentrically to the workpiece centre and/or the concentric main bearings of crankshafts

VIDEO

Catalogs

No catalogs are available for this product.

See all of HELLER‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- Cutting CNC machining center

- CNC machining center with pallet changer

- Horizontal CNC machining center

- Drilling CNC machining center

- Machining center for the automobile industry

- CNC machining center with rotary table

- Direct-drive CNC machining center

- Turning-milling machine

- CNC turning-milling center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.