Automatic coating machine CBC 200

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

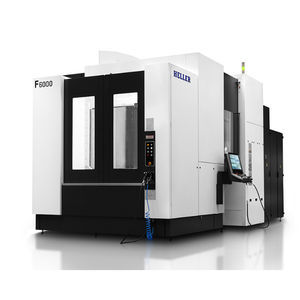

CBC 200 HELLER coating modules are used for coating cylinder bores in crankcases using CBC technology (CylinderBoreCoating). The CBC thermal coating process, developed in cooperation with Daimler, is based on electric arc wire spraying and is the only process that can be used for higher production volumes. HELLER CBC, therefore, is expanding our process chain in crankcase production by a crucial operation. Systems as flexible as you like – as a bypass solution or a precisely tailored manufacturing concept.

Key facts

The benefits of HELLER CBC at a glance

thermal coating process for cylinder bores based on electric arc wire spraying

4-stage process: roughening, coating, finish boring and honing

coating of all cylinder faces with bore diameters from 70 to 150 mm

reduced fuel and oil consumption thanks to 50 % lower friction coefficients between piston and cylinder

size and weight saving with the motor: more compact crankcase design due to the absence of cast iron liners and shorter distance between the cylinder bores

coating with the HELLER CBC 200 coating module

CBC process integrated into every large series production facility – as a bypass solution or a complete process from HELLER

The mechanical foundation of the CBC coating process is the adequate preparation of the cylinder bore. A number of different roughing technologies are available for producing different surface conditions. To achieve the quality required for the coating process carried out in the second step, it is vital to create a structured surface quality whilst guaranteeing a precisely defined bore centre.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HELLER‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.