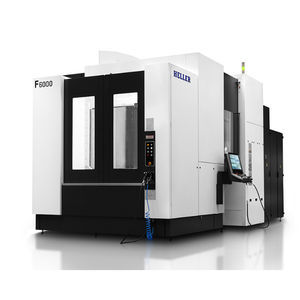

4-axis CNC machining center MPC 10000horizontalwith rotary tablefor the automobile industry

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- horizontal

- Structure

- with rotary table

- Applications

- for the automobile industry, heavy-duty

- Other characteristics

- multi-spindle

Description

HELLER MPC 10000 4-axis machining centres are optimally suited for integration into flexible manufacturing systems and for the efficient series production of heavy-duty vehicle components. The one thing that's needed is: power. Wherever machining centres have to work to their limit, MPC 10000 4-axis machining centres are within their comfort zone. Extremely high feed forces ensure performance and the special machine concept guarantees stability with maximum precision. The automatic head changer also achieves maximum flexibility in production.

Key facts

designed for optimal integration into flexible, interlinked manufacturing systems and the 24/7 series production of heavy-duty vehicle components

24/7 series production of heavy-duty automotive components

horizontal machining unit with standardised fixture for boring, milling and multi-spindle heads

automatic head changer for optimised flexibility in series production

workpieces automatically loaded into the work area from above (direct load)

designed for high process forces when using large machining heads

Robust basic structure: cross-bed and travelling column in gated design

maximum stability in the flow of forces through topology-optimised structural components from steel

optimised flexibility thanks to the use of application-specific machining heads

automatic head changer

magazine for machining heads at the rear of the machine

machine bed carries the X- and the Z-axis in a cross bed arrangement

the machine column traverses in the X-direction and carries the machining unit

machining unit traverses in the Y-direction, compactly integrated into the machine column

VIDEO

Catalogs

No catalogs are available for this product.

See all of HELLER‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- Drilling CNC machining center

- Machining center for the automobile industry

- Turning-milling machine

- CNC turning-milling center

- CNC machining center with rotary table

- 4-axis CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.