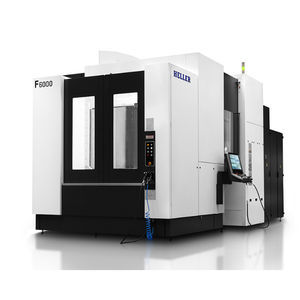

Transfer line TRS

Add to favorites

Compare this product

Description

Modular transfer line systems for high volumes in the series manufacture of light-duty to heavy-duty automotive components

HELLER offers the TRS modular transfer line system, an efficient special solution for high volumes in the series manufacture of light-duty to heavy-duty automotive components. Available as stand-alone machines and as transfer lines with integrated workpiece transport system for the cyclical transport of workpieces from one station to another. Dedicated for special applications, HELLER TRS transfer line systems are always optimally tailored to the requirements of the workpiece type to be produced and to the machining operation.

Key facts

transfer line systems for 24/7 series production of light-duty or heavy-duty automotive components, designed for high volumes

custom machines for special applications (e.g. roughing and finishing of automotive components, complex milling operations, machining of cylinder bores, crankshaft and camshaft bores, valve seat machining and other applications)

available as stand-alone machines for direct loading and as transfer lines with integrated workpiece transport system

standardised, modular construction

TRS stations with horizontal or vertical spindle unit arrangement

one-spindle or multi-spindle TRS stations

TRS stations for special processes, such as line boring

always optimally tailored to the requirements of the workpiece type to be produced and to the machining operation

Stable basic structure in various configurations

high stability and damping through topology-optimised structural components

optimised flow of forces through compact design

VIDEO

Catalogs

No catalogs are available for this product.

See all of HELLER‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.