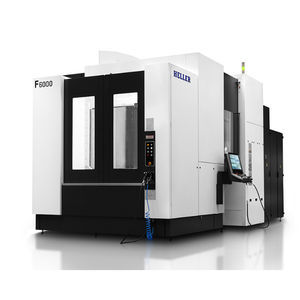

CNC milling-turning center C seriesuniversal5-axisrotating table

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- universal

- Number of axes

- 5-axis

- Structure

- rotating table

- Other characteristics

- high-precision, high-productivity, high-power, direct-drive

- X travel

800 mm, 1,000 mm, 1,250 mm, 1,600 mm

(31.5 in, 39.37 in, 49.21 in, 62.99 in)- Y travel

1,200 mm, 1,250 mm, 1,400 mm

(47.24 in, 49.21 in, 55.12 in)- Z travel

1,400 mm

(55.12 in)- Machine weight

2,000 kg, 4,000 kg

(4,409.25 lb, 8,818.49 lb)

Description

Powerful milling is a matter of course for HELLER machining centres. If the turning machining strategy is added, conventional milling dimensions are soon forgotten. The net result from turning, milling and HELLER's expertise in machine construction is our C-series 5-axis milling/turning machining centre – unique in terms of output, reliability and resilience.

Key facts

flexible in use for powerful 5-sided and simultaneous 5-axis machining, as well as turning with positioned rotary axes

spindle units with swivel head or tilting head kinematics

robust machine design, combined with powerful, high-torque spindle technology

part costs optimised by reducing the number of clamping positions and complete machining in one set-up

can be used for a wide range of different parts and materials

machines with pallet changer (CP) are optimal for series production

machines with table loading (CT) for workshop-based production and small batch sizes

easy to automate with workpiece or pallet automation

Machine concept

Structural dynamic examinations as early as the development phase are key to a milling-turning machining centre achieving an equally high performance in both the milling and turning machining strategies. Both the machine concept and the entire process design of our C-series 5-axis milling-turning machining centres are the result of a comprehensive simulation process. For you, this means: reliable productivity and precision in two fully-fledged production processes.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HELLER‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Cutting CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- Drilling CNC machining center

- Machining center for the automobile industry

- Turning-milling machine

- CNC turning-milling center

- Direct-drive CNC machining center

- CNC machining center with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.