- Robotics - Automation - Industrial IT

- Automation

- CANopen communication module

- Helmholz GmbH & Co. KG

USB communication module 700-600-CAN12CANopenPLCprogrammable

Add to favorites

Compare this product

Characteristics

- Bus

- USB, CANopen

- Other characteristics

- PLC, programmable

Description

The CAN 300 PRO module, for use in an S7-300* from Siemens, enables connection of CAN participants with the automation device.

The module can be plugged into either the central frame or the expansion frame. It supports CAN 2.0A (11 bit) and CAN 2.0B (29 bit) frames with a freely selectable transfer rate from 10 kbps to 1 Mbps.

The CAN 300 PRO can send and receive CAN telegrams in Layer 2 mode. In the CANopen master mode, the data of the CANopen slaves can be processed as a process image table in the PLC.

Use as a CANopen slave is also possible. For standard applications, such as motor control with CANopen, application examples are available. In addition, handling blocks for the SAE J1939 protocol are available.

There are 16 freely settable timers available in the CAN 300 PRO. Each timer can trigger a freely programmable CAN telegram. This means the synchronous protocols widely available in drive and servo control are easy to implement using the CAN 300 PRO.

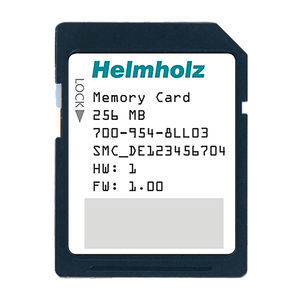

A DIP switch for setting the transfer rate and station address facilitates commissioning. An optional Micro memory card stores the project. In this way, replacement of the parameterization or the module during servicing can be carried out quickly.

6 LEDs indicate the operating status of the module. There is a USB interface for diagnostics and parameterization.

The CAN 300 PRO also works in the extended ambient temperatures of -25 °C to +60 °C.

Layer 2, 11 bit and 29 bit (CAN 2.0A/B)

DIP switches for address + transfer rate

Memory card for project backup (optional)

Extended ambient temperature

Catalogs

CAN 300 PRO

2 Pages

Related Searches

- Ethernet switch

- Digital master module

- I O module

- Industrial network switch

- Managed ethernet switch

- Analog master module

- Digital I O module

- Gigabit Ethernet ethernet switch

- DIN rail ethernet switch

- RJ45 ethernet switch

- Transceiver module

- Fieldbus I O module

- Waterproof ethernet switch

- Communication gateway

- Unmanaged ethernet switch

- Redundant ethernet switch

- FOUNDATION Fieldbus gateway

- Industrial gateway

- Industrial communication router

- Ethernet communication router

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.