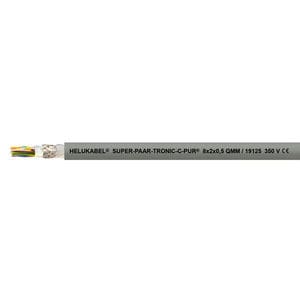

DIN electrical cable SUPERTRONIC®-C-PVCoil-resistantflame-retardantround

Add to favorites

Compare this product

Characteristics

- Format

- DIN

- Protection

- flame-retardant, oil-resistant

- Configuration

- round, stranded

- Core material

- copper

- Applications

- for robotics, for drag chains

- Material of the insulation

- PVC-sheathed

- Color of the insolation

- gray

- Norms

- IEC

- Other characteristics

- flexible, multi-core

- Nominal voltage

350 V

- Temperature

Min.: -40 °C

(-40 °F)Max.: 70 °C

(158 °F)- Cross-section

Min.: 0.14 mm²

(0 in²)Max.: 0.34 mm²

(0 in²)

Description

Test voltage core/core - 1500 V

Breakdown voltage - 3000 V

Coupling resistance - at 30 MHz, approx. 250 Ohm/km

Minimum bending radius - flexible 7.5x Outer-Ø

fixed 4x Outer-Ø

Copper wire bare, extra finely stranded

Wire structure:

0.14 mm²: approx. 18 x 0.1 mm

0.25 mm²: approx. 32 x 0.1 mm

0.34 mm²: approx. 42 x 0.1 mm

Core insulation: PVC acc. to DIN VDE 0207-363-3 / DIN EN 50363-3 (compound type TI2)

Core identification acc. to DIN 47100, colour coded

x = without protective conductor

Cores stranded in layers with optimally matched lay lengths

Fleece wrapping

Screen: braided screen of tinned copper wires, approx. coverage 85%

Outer sheath: Special-PVC acc. to DIN VDE 0207-363-4-1 / DIN EN 50363-4-1 (compound type TM2)

Sheath colour: grey (RAL 7001)

Length marking: in metres

largely resistant to: oil,

for details, see "Technical Information"

low adhesion

suitable for use in drag chains

the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC

These cables are ideal for the use in drag chain applications; for frequent lifting and bending stress in machine and tool construction, in robotics and on permanently moving machine parts. A long service life also guarantees reliable function and high efficiency. EMC= Electromagnetic Compatibility; in order to optimise EMC properties, we recommend a double-sided and all-round large contact area of the copper braiding.

Catalogs

Related Searches

- Electrical connector

- Electrical cable

- Data electrical connector

- Copper cable

- Copper electrical cable

- Power cable

- Insulated cable

- Multi-strand cable

- Insulated electrical cable

- Conduit gland

- Female electrical connector

- Stranded electrical cable

- Data electrical cable

- Flexible cable

- Waterproof cable gland

- Male electrical connector

- Flexible electrical cable

- Metal cable gland

- PVC-sheathed cable

- Industrial cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.