- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

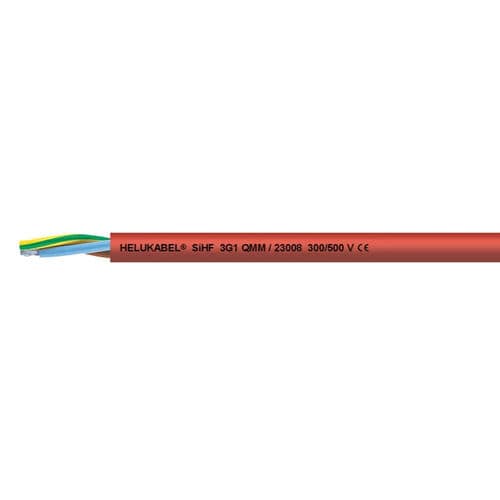

DIN electrical cable SiHFflame-retardantstrandedcopper

Add to favorites

Compare this product

Characteristics

- Format

- DIN

- Protection

- flame-retardant

- Configuration

- stranded

- Core material

- copper

- Applications

- control

- Norms

- IEC

- Other characteristics

- flexible, halogen-free, connection, multi-core

- Nominal voltage

300 V, 500 V

- Temperature

Max.: 180 °C

(356 °F)Min.: -60 °C

(-76 °F)- Cross-section

Max.: 35 mm²

(0.05 in²)Min.: 0.5 mm²

(0 in²)

Description

increased temperature resistance

tinned wire

Silicone control and connection cable in alignment with DIN VDE 0250-1, DIN VDE 0285-525-2-83 / DIN EN 50525-2-83

Permissible operating temperature of the conductor - +180°C

Test voltage core/core - 2000 V

Breakdown voltage - 4000 V

Minimum bending radius - flexible 7.5x Outer-Ø

fixed 4x Outer-Ø

Copper wire tinned, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Core insulation: silicone

Core identification acc. to DIN VDE 0293-308,

2 - 5 core(s): colour coded

6 - 25 core(s): black cores with consecutive labeling in white digits

Protective conductor: starting with 3 cores,

G = with protective conductor GN-YE, in the outer layer,

x = without protective conductor

Cores stranded in layers with optimal lay lengths

Outer sheath: silicone

Sheath colour: redbrown

Length marking: in metres

resistant to: ozone, oxygen, weathering effects, alcohols, dilute acids, alkalis, saline solutions, oxidising agents, high molecular weight oils, vegetable and animal fats, plasticisers and clophen, seawater

halogen-free

high flash point

leaves an insulating layer of SiO2 when exposed to flames

no significant changes in dielectric strength and insulation resistance even at higher temperatures

halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1

corrosiveness of combustion gases acc. to DIN VDE 0482-754-2 / DIN EN 60754-2 / IEC 60754-2

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC

the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Electrical connector

- Electrical cable

- Data electrical connector

- Copper cable

- Copper electrical cable

- Power cable

- Insulated cable

- Conduit gland

- Insulated electrical cable

- Female electrical connector

- Multi-strand cable

- Stranded electrical cable

- Data electrical cable

- Waterproof cable gland

- Flexible cable

- Male electrical connector

- Flexible electrical cable

- Metal cable gland

- PVC-sheathed cable

- Industrial cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.