- Power Transmission - Mechanical components

- Mechanical Transmission

- Friction brake

- HEMA Maschinen- und Apparateschutz GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

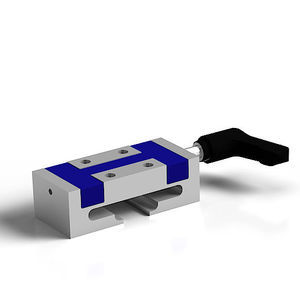

Friction braking element LinClamp S/SK/SA Serieswith pneumatic releaselinear guide

Add to favorites

Compare this product

Characteristics

- Type

- friction

- Operation

- with pneumatic release

- Other characteristics

- linear guide

Description

LinClamp clamping and braking systems are designed to brake and retain masses moving axially over linear guide rails and elements. Their design, surface quality, and dimensional, shape, and positional tolerances are equivalent to the commercially available linear guide rails.

The right clamping system for every application

Our LinClamp clamping systems are available in two versions: as a classic design that opens when compressed air is applied and eliminates the need for compressed air or compressed air failure (fail-safe) or as an active version that clamps when pressurized.

LinClamp clamping systems are available in many sizes and for both low and high carriages.

LinClamp S/SK released

Compressed air is applied to the chamber between the two spring steel diaphragms. This deforms the spring steel sheets elastically and shortens them in the horizontal direction. The clamp body is deformed in such a way that it comes into contact at the top with the spring steel sheets and expands at the bottom around the brake shoes. This lifts the brake shoes from the rail, making it freely moveable.

LinClamp S/SK clamped

The chamber between the two spring steel diaphragms is vented. The spring steel sheets spring back to their normal position and expand the upper part of the clamping body. However, this expansion at the top simultaneously leads to a narrowing at the bottom. This narrowing causes the brake shoes to press against the rail and to clamp it.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HEMA Maschinen- und Apparateschutz GmbH‘s catalogsOther HEMA Maschinen- und Apparateschutz GmbH products

Clamping and Braking systems

Related Searches

- Clamp

- Friction brake

- Workholding component

- Hydraulic clamping device

- Pneumatic brake

- Manual workholding component

- Pneumatic clamping element

- Shaft clamping device

- Brake with pneumatic release

- Hydraulic clamping element

- Pneumatic clamping system

- Rail clamping element

- Linear guide clamping element

- Steel clamping system

- Compact clamping system

- Cam clamping element

- Shaft clamping system

- Tube clamping system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.