- Building - Construction

- Production of building materials

- Concrete block making machine

- Henan Oreco Environmental Engineering Technology C

- Products

- Catalogs

- News & Trends

- Exhibitions

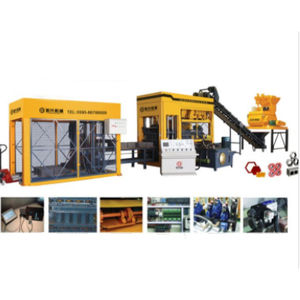

Concrete block making machine automaticstationary

Add to favorites

Compare this product

Characteristics

- Material

- concrete

- Operational mode

- automatic, stationary

Description

Automatic Road Block Making Machine

DESCRIPTION

Imported hydraulic main parts and seals, hydraulic components use high dynamic performance proportional valves, which can adjust the oil quantity and pressure according to different working requirements to precisely control the movement of key parts.

Main technical features

• The machine realizes the integration of machine, electricity and liquid, PLC computer automatic control, monitoring every link in the whole process, realizing fault self-locking, fault detection and production statistics.

• Imported hydraulic main parts and seals, hydraulic components use high dynamic performance proportional valves, which can adjust the oil quantity and pressure according to different working requirements to precisely control the movement of key parts.

• Full-featured, advanced technology, suitable for the production of various types of concrete blocks, standard bricks, perforated bricks, pavement bricks, good product quality, high pressure resistance, accurate size, etc., and the secondary cloth device can produce a variety of color tiles, color Surface grass and bricks along the road.

• Suitable for sand, stone chips, slag, coal gangue, coal ash, fly ash, bottom slag and waste construction waste.

Raw materials: Our technology can be widely used in power plant steel mill wet ash, dry ash, mixed ash, slag, spontaneous combustion gangue, stone powder, stone nitrate (pebbles), sand, ceramsite, tailings sand, volcanic ash ( Slag), steel slag, calcium carbide slag, water quenching slag, air quenching slag, heavy slag, smelting slag, water slag, dry slag, sulfuric acid slag, phosphate fertilizer slag, alkali slag,

Other Henan Oreco Environmental Engineering Technology C products

AUTOMATIC BLOCK MAKING MACHINE

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.