- Electricity - Electronics

- Cable, Connector, Enclosure

- Aluminum alloy conductor rail

- Henan Tong-Da Cable Company

- Products

- Catalogs

- News & Trends

- Exhibitions

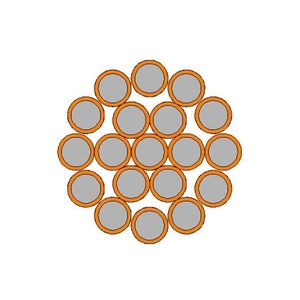

Aluminum alloy conductor rail AAACpowerinductivereinforced

Add to favorites

Compare this product

Characteristics

- Material

- aluminum alloy

- Electrical characteristics

- power, inductive

- Protection level

- standard, IEC, high-strength, reinforced

Description

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum-alloy to achieve a high strength-to-weight ratio; affords good sag characteristics.

AAAC conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.

The aluminum alloy conductors are used in replace of single-layer ACSR conductors to reduce power loss in overhead distribution and transmission lines,when replacing the aluminum conductor steel reinforced , the AAAC can save 5-8% of the construction cost.

AAAC referred to have higher strength but lower conductivity than pure aluminum Being lighter, alloy conductors can sometimes be used to advantage in replace of the more conventional ACSR.

ASTM B399, BS EN50183, BS 3242, DIM 48201, IEC 61089

Aluminum alloy conductors have a number of advantages over the use of the ACSR or AAC(all aluminum conductors). Lower power losses than for equivalent single aluminum-layer ACSR conductors. (The inductive effect of the steel core in the ACSR is eliminated).

1. Simpler fittings than those required for ACSR.

2. Excellent corrosion resistance in environments conducive to galvanic corrosion in ACSR.

3. Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

Outside diameters are the same as for standard ACSR conductors, permitting interchangeability of 4. fittings.

5. Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

6. High tensile strength as compared to AAC conductor.

7. Higher conductivity as compared to ACSR conductor

Other Henan Tong-Da Cable Company products

Bare Conductor

Related Searches

- Electrical cable

- Copper cable

- Copper electrical cable

- Power cable

- Insulated cable

- Multi-strand cable

- Insulated electrical cable

- Stranded electrical cable

- Flexible cable

- Flexible electrical cable

- PVC-sheathed cable

- Industrial cable

- IEC electrical cable

- PVC-sheathed electrical cable

- Armored cable

- Industry electrical cable

- Single-conductor cable

- Shielded electrical cable

- Single-core electrical cable

- Control electrical cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.