- Packing - Handling - Logistics

- Handling and Lifting

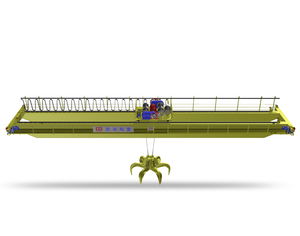

- Double-girder overhead travelling crane

- Henan Weihua Heavy Machinery Co., Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Double-girder bridge crane largelightweight

Add to favorites

Compare this product

Characteristics

- Type

- double-girder

- Other characteristics

- large, lightweight

Description

The retrieval device adopts a fork arm structure, which can effectively achieve fast retrieval and placement of items through the joint action of various operating mechanisms, improving work efficiency.

2. Adopting a three in one drive mechanism, C-wheel structure, modular assembly, and ensuring the installation accuracy of each mechanism by processing the bridge as a whole.

3. Adopting a rigid anti shake telescopic arm device to ensure fast and accurate retrieval and positioning.

4. Adopting a double-layer trolley structure, the upper trolley is a rotating trolley that can lift materials in all directions within a 360 ° range, adapting to multi angle lifting.

5. The small car has been equipped with an anti rollover hook device, making the crane safer and more reliable, and preventing all safety hazards from occurring.

6. The running mechanism of the large and small vehicles has added a horizontal wheel set, which overcomes the misalignment of the liquid sand mold caused by the running impact, ensures the good molding of the castings, and improves the product quality of transporting materials.

7. Adopting a circular drag chain power supply device reduces the overall height of the machine and lowers the cost of the factory building.

8. The bridge adopts a lightweight design concept and finite element analysis technology. Based on the characteristics of the materials, the structural parameters are designed reasonably to ensure the reliability of product quality.

Catalogs

No catalogs are available for this product.

See all of Henan Weihua Heavy Machinery Co., Ltd‘s catalogsOther Henan Weihua Heavy Machinery Co., Ltd products

Double girder overhead crane

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.