- Packing - Handling - Logistics

- Storage

- Mixing tank

- Hengfengtai Precision Machinery Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Mixing tank for the pharmaceutical industryfor wastewaterfor pharmaceutical products

Add to favorites

Compare this product

Characteristics

- Function

- mixing

- Product applications

- for liquids, for wastewater, for the pharmaceutical industry, for chemical products, for pharmaceutical products, for low-viscosity materials, for high-viscosity materials

- Material

- stainless steel, carbon steel

- Type

- double-walled

- Applications

- industrial, for agricultural applications, for chemical applications, for pharmaceutical applications, for wastewater treatment

- Other characteristics

- vertical, horizontal, with agitator, high-volume, with mixer

- Capacity

Max.: 50,000 l

(13,208.603 gal)Min.: 50 l

(13.209 gal)

Description

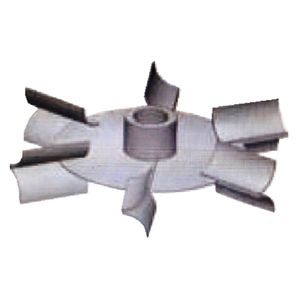

Agitator tank/mixing tank

1, Method: Single layer, insulated or heated structure,volume optional: such as 50L, 100L, 200L, 300L, 500L, 600L, 1000L ~ 10000L or other volumes.

2, optional heating: the use of electric heating rod inserted into the jacket, heating uniform without cold zone. Heat transfer oil or water is injected into the jacket as the heating medium to generate heat energy to heat the materials in the tank.

3, optional heating function, material heating temperature: ≤150℃; Material heating time: 20min ~ 90min(depending on process requirements).

4, optional heating function, temperature control: the electric couple measurement temperature and temperature controller connection to measure and control the temperature (temperature difference ±≤1°C), and can adjust the material temperature level. The temperature controller is installed in the electric control box, and the temperature transmission rod is inserted directly into the bottom of the tank, so that the material liquid can indicate the temperature when it is used in the lowest position.

5, tank body: internal surface mirror polishing treatment, roughness Ra≤0.4μm.

6, top cover: EHA standard oval head can be equipped with atmospheric pressure manhole cover, but also for two open movable cover, easy to clean, internal and external surface mirror polishing treatment (roughness Ra≤0.4μm).

7, the inner tank bottom structure: EHA standard oval bottom head, the bottom is in the center of the sanitary discharge port, can also be made into a conical bottom or diagonal bottom side according to customer needs.

Catalogs

No catalogs are available for this product.

See all of Hengfengtai Precision Machinery Co.,Ltd‘s catalogsOther Hengfengtai Precision Machinery Co.,Ltd products

Mechanical mixing equipment technology Solution

Related Searches

- Vessel

- Inox vessel

- Vertical vessel

- Industrial vessel

- Liquid vessel

- Horizontal vessel

- Water vessel

- Vessel for chemical applications

- Vessel for pharmaceutical applications

- Double-walled tank

- Agriculture tank

- Mixing vessel

- Carbon steel vessel

- Tank with agitator

- High-volume tank

- Vessel for the pharmaceutical industry

- Wastewater tank

- Pharmaceutical product tank

- Chemical product tank

- Tank with mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.