- Metrology - Laboratory

- Inspection and Monitoring

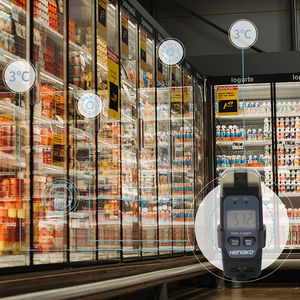

- Temperature and humidity data-logger

- HENGKO Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Temperature and humidity data-logger HK-J9A200 series4-20mAwirelessRS-485

Add to favorites

Compare this product

Characteristics

- Measured quantity

- temperature and humidity, 4-20mA

- Connector type

- wireless, RS-485

- Display

- with LCD display

- Applications

- for monitoring, for food applications, for medical applications, storage, for cold chain monitoring

- Other characteristics

- high-accuracy, intrinsically safe

Description

Cold chain management and process monitoring: for optimisation of product quality and loss minimisation.The legislators require that the minimum temperature within the entire cold chain for deep-frozen goods (for example food) is minus 18 degrees Celsius, whereby there may only be short-term fluctuations of a maximum of 3 degrees Celsius. HK-J9A200 series wireless temperature and humidity data logger adopts high precision sensor provide meaningful support at the highest technical level so that you are always able to optimally meet all of the legal specifications with your cold chain and process monitoring in this context!

Cold chains evolved due to a growing need for temperature-controlled logistics that could safely transport large quantities of food over great distances.

Over time, however, cold chains have become an essential part of modern supply chain solutions to transport more sensitive or vital cargo over great distances through diverse climatic conditions.

Cold chains are vital in the storage and transport of the following products:

Food & Beverages

High-end foodstuffs

Fruits & vegetables

Meat & seafood

Poultry & dairy

Processed & ready-to-eat food

Temperature-sensitive Chemicals

Paint

Volatile chemicals

Medical Goods

Vaccines

Pharmaceuticals & healthcare products

Biologics (tissue samples, live cultures, etc., meant for medical research)

Other Temperature-sensitive Items

Plants & flowers

Synthetic products

High-tech electronic/electrical components

Photographic film

IDEA:

RELATIVE HUMIDITY MEASUREMENT TRANSMITTER AND SOLUTIONS MANUFACTURER. TEMPERATURE HUMIDITY MEASUREMENT & MONITORING FOR VARIOUS INDUSTRIAL APPLICATIONS.

Catalogs

No catalogs are available for this product.

See all of HENGKO Technology Co., Ltd.‘s catalogsOther HENGKO Technology Co., Ltd. products

Handheld Dew Point Meter - Humidity, Dewpoint, Temp

Related Searches

- Datalogger

- Temperature data logger

- Data logger with screen

- USB data logger

- Wireless datalogger

- Data logger with LCD display

- Battery-powered datalogger

- Monitoring data logger

- Compact data logger

- Storage data logger

- Humidity data logger

- Multi-channel data logger

- Pressure data logger

- Data logger for food applications

- Digital data logger

- Temperature and humidity data logger

- Data-logger for pharmaceutical applications

- Current data logger

- High-accuracy data logger

- Data logger for medical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.