Fully automatic refilling-stations, when used as part of a completely automated manufacturing process, ensure material-specific preparation, homogenous consistency and a continuous supply of material – all with greater operating convenience and increased working and functional reliability. This means that production downtimes are now a thing of the past.

They are controlled by the mixing and dosing system with the help of monitoring by means of fill-level sensors in the material containers. Controlled agitators with an adjustable speed range and a programmable timer ensure optimum homogenization of the reactive materials. All refilling stations can be equipped with different stirring elements, depending on the material. Existing production plants can be retrofitted.

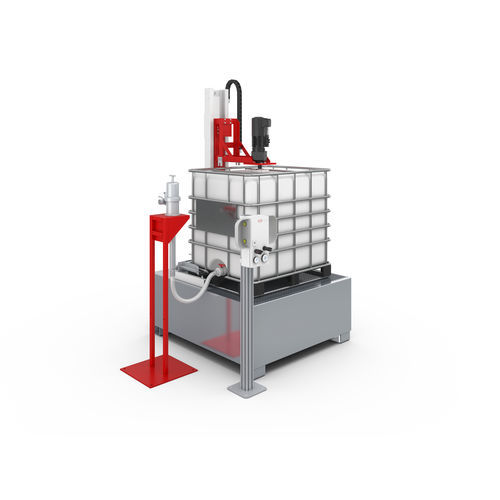

The BIG ELEVATOR shown is an automatic container-type refill station with lifting device and regulated agitator mechanism for liquid and thixotropic products (e. g. polyols).