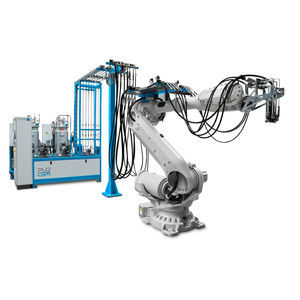

Polyurethane spray unit PUR-CSM SKIN

Add to favorites

Compare this product

Characteristics

- Sprayed material

- polyurethane

Description

Production of PU spray skins for automotive and non-automotive applications

The benefits of spray technology will pay off especially when it comes to finishing complex parts such as dashboards or door panels. A layer of aliphatic paint is initially applied by In-Mould Coating (IMC). This UV-resistant coating is then reinforced with a sprayed aromatic polyurethane. Compared to PVC, this combination exhibits greatly improved haptic properties and extremely low emission values. As the coating will only be applied where needed, up to 10% material savings can be achieved. Thus, spray skin is not only one of the most top-grade surface technologies, it is also very attractive in terms of cost. In addition, the user will achieve a reduced specific density at the same skin thickness. Hennecke supplies tailor-made systems technology for PUR-CSM SKIN applications. Depending on the design, these lines are fully suitable for large-scale production.

Catalogs

PUR-CSM SKIN LINES

10 Pages

PUR-CSM PREG LINES

22 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.