- Machine-tools

- Machine Tool Accessory

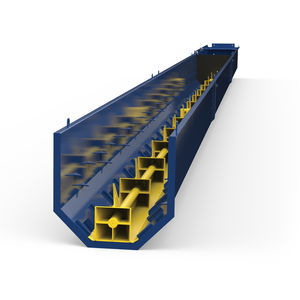

- Belt conveyor

- HENNIG FRANCE

Custom-made conveyor beltchipsuction

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Transported product

- chip

- Other characteristics

- custom-made, suction

- Speed

Max.: 3,300 mm/min

(2.17 in/s)Min.: 800 mm/min

(0.52 in/s)

Description

Any of our conveyor systems can be custom engineered to suit your needs exactly. Every chip management system we deliver comes equipped with our standard features, and any other options you need to get the job done. We've seen it all and know how to help you manage any chip load and chip type.

Conveyor networks

For high-volume manufacturers, Hennig’s integrated conveyor networks can automate the removal of chips on one or all of the machine tools in the shop. This systems allows the user to spend more time manufacturing and less time sweeping and moving chips.

•Suction canal

allows the system to evacuate dust and gas during dry machining

•Controls

Standard VFD or push-button control box

•Overhead torque limiter

•Custom coolant tanks & filtration

integrated or auxiliary

•Custom chutes

•Heavy-duty hardened rails and curves

•Air knife (for removing sticky chips from belt at the discharge end)

•Wear resistant bottom frame

•On-site installation

•Casters

•Chip Shredder

•Swarfs Centrifuge

•Swiveling Chutes

manual or automated

•Chips Compactor

•Vibrating Table

Applications

•Machines with suction devices for fumes mist and dust

•Air tight space from machine to discharged tunnel

•We can accommodate most applications. You let us know what you need, we'll design and manufacture it.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HENNIG FRANCE‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Stainless steel conveyor

- Modular conveyor

- Transfer rail conveyor

- Mobile conveyor

- Heavy load rail conveyor

- Part conveyor

- Round protective bellows

- Plastic protective bellows

- Conveyor for the automotive industry

- Height-adjustable conveyor

- Accordion protection protective bellows

- Trough conveyor

- Chip conveyor

- Conveyor for heavy-duty applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.