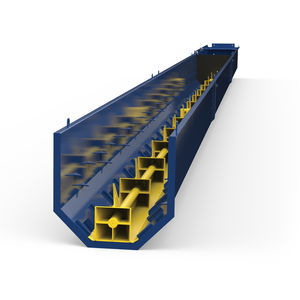

Sludge conveyor magnetic beltmobilechip

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic belt

- Construction

- mobile

- Transported product

- chip, sludge

- Options and accessories

- with integrated coolant filtration

Description

There’s an Easier Way to Keep Your Coolant Clean

Some manufacturers have chip management systems that require filtration, however, their conveyor systems aren’t able to complete this task with their current setup. Hennig designed and manufactured a mobile filtration system that allows the customer to properly filter and maintain their coolant without having to purchase or install an entirely new system.

Your coolant traditionally needs to be changed every 6-8 weeks, taking your machine down for the day. The mobile filtration system allows you to wait 3-6 months before having to clean out your coolant, keeping your team focused on making chips instead of finding ways to get them out of your coolant.

Reduce your downtime

Instead of having your machines down every 6-8 weeks for an extensive cleaning, you’re able to run the mobile sludge sucker across the shop, extending your coolant usage for 3-6 months.

Mobile Capabilities to move from machine to machine

With the Portable Sludge Sucker, you’re able to clean out your coolant within 2-4 days of running. You can easily move it from machine to machine.

Avoid backups due to extensive cleaning

When your machine goes down, you’re not making chips. When you’re not making chips, you’re not making money. The Portable Sludge Suckers allows you to keep your machines running, avoiding backups due to clogged pumps and overflowing coolant pans.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HENNIG FRANCE‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Stainless steel conveyor

- Modular conveyor

- Transfer rail conveyor

- Mobile conveyor

- Conveyor system

- Part conveyor

- Heavy load rail conveyor

- Conveyor for the automotive industry

- Height-adjustable conveyor

- Trough conveyor

- Chip conveyor

- Conveyor for the metallurgical industry

- Conveyor for heavy-duty applications

- Small load conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.