- Hydraulics - Pneumatics

- Filter and Separator

- Water filter

- Hertz Kompressoren GmbH

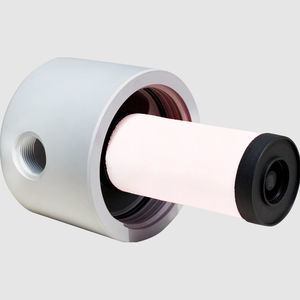

Liquid filter HGO serieswatercompressed airbasket

Add to favorites

Compare this product

Characteristics

- Designed for

- liquid, water, compressed air

- Filtration element

- basket

- Applications

- dust, for compressors

- Material

- aluminum, PVC

- Other characteristics

- low pressure

- Operating pressure

16 bar

(232.06 psi)- Filtration size

Min.: 0.01 µm

Max.: 1 µm

- Flow

Min.: 0.42 m³/min

(14.832 ft³/min)Max.: 45 m³/min

(1,589.16 ft³/min)

Description

Hertz Compressed Line Filters have been designed to answer the current requirements of compressed air filtering. It enables more comfortable usage for end user better endurance, higher efficency with lower pressure drop and more port size options.

Filters

The compressed air coming from compressor may contain unwanted elements such as oil, dust and humidity. The air in the external environment will also affect the quality of the final product. This air must be filtered prior to the final stage of production.

The line filters have 4 ranges of efficiencies, 235 psi (16barg) - 1/4” to 3” NPT/BSP pipe sizes. A protected auto float drain (2mm orifice) is standard for reliable removal of liquid contaminants. Zero-porosity aluminum and durable epoxy powder-coat finish, along with a corrosion resistant internal coating gives long service life. Filter combinations are configured to meet specific application requirements Filter comply with PED and perform as per related ISO 8573 standards.

These filters are equipped with differential pressure gauges for easy maintenance and energy efficiency.

Element Features

Hertz offers Superior protection - from 1 micron to 0,01 micron. Durable element construction and efficient drain layer ensures continued performance after optimal element change.

1- Deep pleating also enables a lower pressure drop

2- Supreme collapse resistance due to usage of flutted stainless tube provides strength against pressure drops while improving the performance by passing air diagonally through the element.

3- PVC impregnated foam favours Water / Oil drainage

Hertz Compressed Line Filters have been designed to answer the current requirements of compressed.

Catalogs

No catalogs are available for this product.

See all of Hertz Kompressoren GmbH‘s catalogsOther Hertz Kompressoren GmbH products

Pressurized Air Filters

Related Searches

- Liquid separator filter

- Filter with cartridge

- Solid classifier

- Pressure separator filter

- Centrifugal classifier

- Liquids separator

- Water separator filter

- Basket separator filter

- Gravity classifier

- Compressed air separator filter

- In-line filter

- Dust pre-filter

- High-efficiency pre-filter

- Aluminium filter

- Easy cleaning pre-filter

- Steel separator filter

- Vacuum separator filter

- Water separator

- Suction separator filter

- Low pressure separator filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.