- Hydraulics - Pneumatics

- Filter and Separator

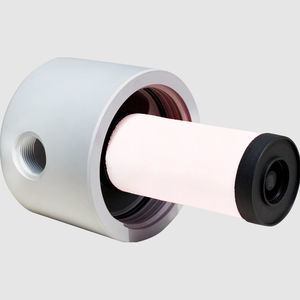

- Oil mist filter

- Hertz Kompressoren GmbH

Oil mist filter HELM series cartridgecoalescingvacuum

Add to favorites

Compare this product

Characteristics

- Designed for

- oil mist

- Filtration element

- cartridge

- Filtration method

- vacuum, coalescing

- Applications

- suction, for vacuum pumps, for compressors, exhaust, for blowers

- Cleaning

- easy cleaning

- Operating pressure

16 bar

(232.06 psi)- Flow

Max.: 340 m³/min

(12,006.987 ft³/min)Min.: 4.25 m³/min

(150.087 ft³/min)- Fluid temperature

80 °C

(176 °F)

Description

HERTZ HELM Series mist eliminators are designed to meet the demand for efficient removal of oil-mist carryover from piston or oil flooded rotary compressors and to capture oil fog, mist, or smoke from exhaust and pressure unloading vents of vacuum pumps and blowers

Capturing oil fog, mist, or smoke from exhaust and pressure unloading vents on oil flooded compressors, vacuum pumps and blowers

Any application requiring Low Delta P coalescing of large air volumes

Vacuum Freeze Drying

Vacuum Out - Gasing

Vacuum Coating

Food Processing

Nailers / Staplers

Industrial Vacuum Processes

Cement & Paper Processing

Mist Eliminators are designed to meet the demand for:

Efficient removal of oil-mist carryover from piston or oil flooded rotary compressors

Long service life

Strength to withstand strenuous operating conditions

Protection from oil slugs or compressor Air/ Oil separator failure

Features

Very Low pressure drop

Large oil catching efficiency

Easy field cleaning

Positive sealing O-rings

Auto Float Drain is Standard

Multiple drain Style Options Available

Increased surface area in a given volume allows low velocity separation of ultra fine oil mist

Elements are grounded to canister minimizing static electricity problems

Mist Eliminator Element

Ultra low pressure drop reduces energy costs.

Positive gasket seals eliminate media bypass

True Air / Oil Separator

Long service life

Catalogs

No catalogs are available for this product.

See all of Hertz Kompressoren GmbH‘s catalogsOther Hertz Kompressoren GmbH products

Pressurized Air Filters

Related Searches

- Liquid separator filter

- Filter with cartridge

- Solid classifier

- Pressure separator filter

- Centrifugal classifier

- Liquids separator

- Water separator filter

- Basket separator filter

- Gravity classifier

- Compressed air separator filter

- In-line filter

- Dust pre-filter

- Aluminium filter

- High-efficiency pre-filter

- Easy cleaning pre-filter

- Steel separator filter

- Vacuum separator filter

- Water separator

- Suction separator filter

- Low pressure separator filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.