- Production Machines

- Other Manufacturing Equipment

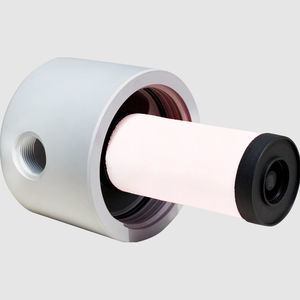

- Pure nitrogen generator

- Hertz Kompressoren GmbH

Pure nitrogen generator HNC series CMSPSAcompact

Add to favorites

Compare this product

Characteristics

- Gas characteristics

- pure

- Technology

- PSA, CMS

- Configuration

- compact

- Other characteristics

- automatic

- Gas purity

95 %

Description

Produce your nitrogen needs continuously with HERTZ HNG series Nitrogen Generator. Save time, money and space. HNG series are very easy to use with its simple structure, compact design and fully automated operation.

Pressure Swing Adsorption (PSA) type Nitrogen Generation system is used to separate and enrich Nitrogen from Oxygen employs CMS (Carbon Molecular Sieve) for adsorbent. Carbon Molecular Sieve (CMS) adsorbs Oxygen and Water Vapor molecules under certain pressure - while allowing Nitrogen to pass through.

The nitrogen molecules (4.3 Angstrom in size) passes through the column, but the oxygen molecules (3.9 Angstrom in size) are adsorbed on the carbon molecular sieve (4 Angstrom opening).

The cycle is composed of following steps

PSA Process

A. Pressurization Step:

Process to increase adsorption pressure in adsorption tower under selected operation condition.

B. Adsorption Step:

Nitrogen gas is generated under constant pressure.

C. Blow Down Step:

Restoring in the adsorption tower.

D. Purge Step:

Stage to restore the adsorption tower completely.

E. Pressure Equalization Step:

Stage in where loss can be reduced by using a part of energy to be lost.

Adsorber System

The Nitrogen Generator consists of two adsorber vessels filled with CMS, a valve assembly, air filters, main pressure regulator, and a product receiver tank. Clean and dry air is directed to one of the adsorber beds where oxygen and water vapor is adsorbed faster than nitrogen in the pore structure of the CMS, thus increasing the nitrogen purity of the product gas stream to the desired level (95 – 99.999 % as required by customer). This product flows out of the top of the adsorber bed, through the ,

Catalogs

No catalogs are available for this product.

See all of Hertz Kompressoren GmbH‘s catalogsOther Hertz Kompressoren GmbH products

Pressurized Air Filters

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.