The pneumatically or hydraulically actuated machine needle shut-off nozzles type HP are used in processing of thermoplastics, principally with low viscosity materials such as: PA, PPS, PE, POM,PP.

In this nozzle’s favour are:

Cycle time reduction, shut-off at the nozzle orifice, withdrawal while dosing.

Finds application in:

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Operation:

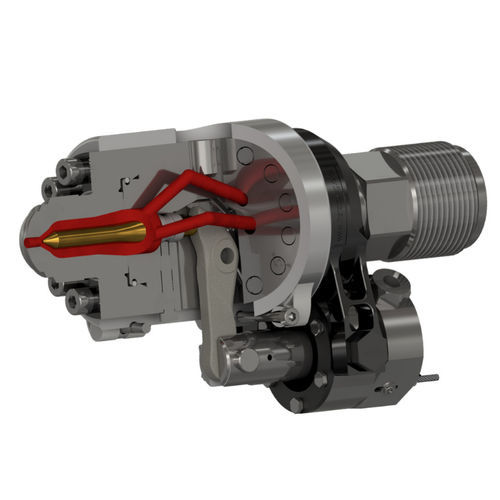

The assembly integrated actuator (pneumatically or hydraulically activated) controls a nozzle-axis positioned needle via a lever mechanism. The melt flow is therefore process dependently separated at the nozzle orifice. The needle mechanism is constructed in such a way, that with over-pressure an automatic opening of the nozzle is ensured.

Modules for filters, mixers and GAIM-applications complete the range of shut-off nozzle products.

Prevents:

• Filamentation

• Air pockets during screw retraction

• Material leakage when dosing with a withdrawn injection unit

• Material leakage while vertically injecting

Applicable for special applications such as:

• Physical foaming

• Pre-compressing the melt

• Hot-runner injection molding (e.g.. containers, pots)

Supported process control:

• Actuator piston position sensors (indicates if nozzle is “open” or “closed”)

Productivity factors:

• Controlled, clean shut-off of the melt stream

• Shorter cycle times - increase in productivity

• Increased process reliability and repeatability

• Usability with increased back pressure - improved homogenization

• Add-on capability (on tool side)

Options:

• Filter module

• Mixer

• GIT

• Process monitoring with piston position sensors on the actuator