- Robotics - Automation - Industrial IT

- Industrial Software

- Quality control software

- HEXAGON MANUFACTURING INTELLIGENCE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Analysis software BendingStudio XTmeasurementquality controlinspection

Add to favorites

Compare this product

Characteristics

- Function

- analysis, measurement, quality control, inspection, for bending

- Applications

- process

Description

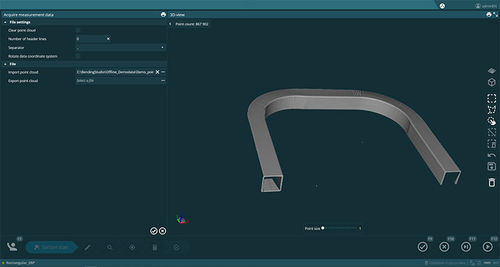

BendingStudio XT links all data and processes involved in the manufacture of bended parts, from production and process planning to manufacturing and quality control.

It is the only tool to meet and combine these requirements with an emphasis on metrological processes. In combination with TubeInspect or Absolute Arm systems, BendingStudio XT offers efficient and customer-oriented solutions with a unique combination of speed, accuracy and flexibility.

For any part, different data is often required for the different stages on the way from the drawing to the tested product. This includes CAD data from design and bend programs and corrections for manufacturing, as well as test and inspection plans or measurement reports and analysis for quality control. But these records are not always 100 percent compatible.

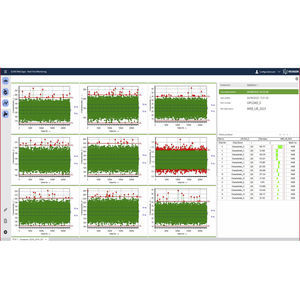

BendingStudio XT is focused on bringing together all parallel data sets belonging to any particular part, allowing manufacturers to monitor, quantify, visualise and document all changes throughout the different process steps.

The platform is based on a simple and clearly structured handling concept featuring a variety of small tools to ease daily work in all areas of bended part manufacturing.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HEXAGON MANUFACTURING INTELLIGENCE‘s catalogsOther HEXAGON MANUFACTURING INTELLIGENCE products

Metrology Software

Related Searches

- Management software solution

- Analysis software solution

- HEXAGON process software

- Windows software solution

- Computer-aided design software

- Online software

- Real-time software solution

- 3D software solution

- Measurement software

- Industrial software solution

- Quality software

- Programming software

- EDM software

- 2D software

- Reporting software solution

- Planning software

- Data management software solution

- CAM software

- Inspection software

- Data analysis software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.