- Robotics - Automation - Industrial IT

- Industrial Software

- Asset management software

- HEXAGON MANUFACTURING INTELLIGENCE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Asset management software HxGNdata analysisreportinginspection

Add to favorites

Compare this product

Characteristics

- Function

- asset management, data analysis, reporting, inspection

- Applications

- for metrology

- Type

- real-time

- Deployment mode

- cloud-based

Description

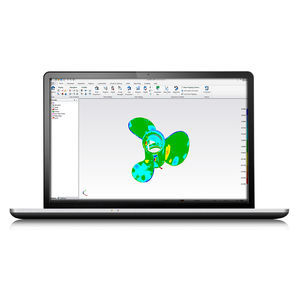

Highly versatile and intuitively easy to use, HxGN NC Measure modular software simplifies the inspection of a wide range of parts directly on the machine tool.

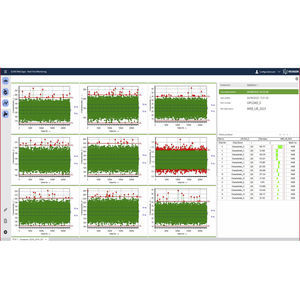

Machine tool measurement is an increasingly important productivity driver, as manufacturers use advances in multisensor inspection technology to save time and improve quality.

A modular, future-proofed software, HXGN NC Measure adapts readily to different machine tool measurement applications, from routine tactile inspection through to highly complex laser scans of clamped parts with up to 5 axes.

The software combines a deep understanding of production processes with a highly intuitive interface to simplify workpiece setup, inspection and the creation of reports that inform rapid decision making.

The core HXGN NC Measure software package offers all the capabilities required to set up workpieces, perform basic measurements and create reports in ASCII format. With additional modules operators can also perform more complex inspection tasks on the machine tool, including the use of laser scanning to capture point clouds over the complete surface of a clamped part, all while benefiting from HXGN NC Measure’s simple, intuitive interface.

In addition to the ground-breaking laser module, users can choose advanced reporting for saving and exporting data in multiple formats and protocols, or a module for automated part adjustment to ensure the best fit for the part on the machine tool. Additionally, HxGN NC Measure can export and import data to m&h NC Gage, which enables machine tool operators to programme offline.

Catalogs

No catalogs are available for this product.

See all of HEXAGON MANUFACTURING INTELLIGENCE‘s catalogsOther HEXAGON MANUFACTURING INTELLIGENCE products

Metrology Software

Related Searches

- Management software solution

- Analysis software solution

- HEXAGON process software

- Computer-aided design software

- Windows software solution

- Online software

- Real-time software solution

- 3D software solution

- Measurement software

- Industrial software solution

- Quality software

- Programming software

- EDM software

- 2D software

- Reporting software solution

- Planning software

- Data management software solution

- CAM software

- Inspection software

- Data analysis software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.