- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

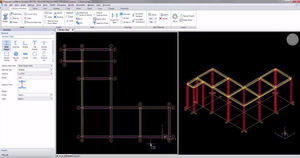

Monitoring software HxGN MineMeasurecontrolaccounting3D

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, control, accounting

- Type

- 3D

Description

Safely and accurately track blasts to minimise loss and dilution with blast movement sensor-software.

Achieve optimal ore yield by minimising ore loss and dilution

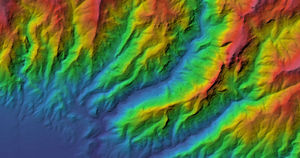

Measured movement with redefined boundaries enable precise understanding of the location of ore versus waste.

Main benefits

Maximise Ore Yield

Controlling ore loss and dilution is critical as the downstream revenue impact can be up to tens of millions of dollars per year.

Reduce waste sent to plant

Accounting for ore movement post-blast leads to maximum ore sent to the mill, and waste to the waste pile.

Maximise potential of the orebody

Accurate blast information enables grade control to recover all of the planned resource and achieve the true life of the pit.

Safely minimise ore loss and increase ore recovery

Blast Movement Monitors (BMMs) increase ore recovery. Remaining dormant until sensing a blast, BMMs are timed to activate when you are ready to detect, resulting in more accurate dig lines and post-blast polygons. BMMs are installed in monitoring holes days or weeks ahead of a blast, making it easy to coordinate installation with production or to stay one step ahead of weather events.

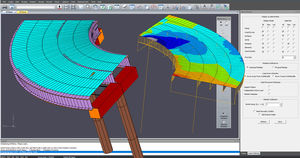

Data from BMMs, which move with the blasted material, results in redefined ore boundaries that accurately reflect measured movement. The software calculates the post-blast 3D movement location of the ore polygons and outputs new dig lines. This enables production teams to dig in the precise location of the ore and waste.

Catalogs

No catalogs are available for this product.

See all of Hexagon PPM‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Monitoring software solution

- Measurement software

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Network software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.