- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

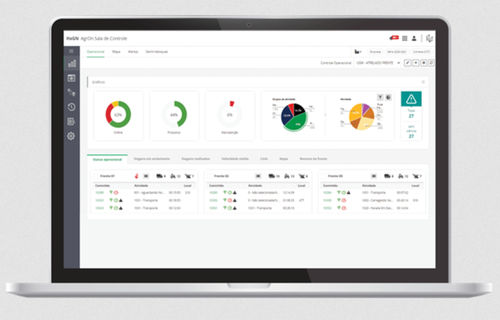

Management software HxGN AgrOn Control Roominterfacemonitoringcontrol

Add to favorites

Compare this product

Characteristics

- Function

- management, interface, monitoring, control

- Applications

- machine, flow

- Type

- real-time

Description

AgrOn Control Room continuously receives data from production locations enabling centralised monitoring and management of all operations. Its easy-to-use interface allows managers to see maps and reports, with real-time alerting of anomalies, incidents, machine performance issues, and any deviation from the cultivation plan to enable timely intervention. AgrOn Control Room works across a wide array of different types of operations and integrates with existing third-party hardware and software.

Characteristics:

Views operations and equipment through georeferenced maps

Generates reports of operating times and stops, productivity, and yields

Shows the start and end time of operations, detailing all data sensed on the machines

Notifications and alerts for processes to flow with maximum efficiency and productivity

Constant monitoring between planned activities and executed operations

It develops decision trees, with a script of standard procedures to be followed in certain occurrences and problems

Ability to work with the Ti5, Ti7, and Ti10 displays

Features add-on modules to cultivation, soil preparation, planting, logistics, and harvesting operations

Benefits:

Tracks hours worked

Provides real-time information

Monitors all machine and equipment

Increases operations efficiency

VIDEO

Catalogs

No catalogs are available for this product.

See all of Hexagon PPM‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Control software solution

- Online software

- Real-time software solution

- Design software solution

- 3D software solution

- Monitoring software solution

- Measurement software

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Automated software

- Network software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.