- Materials - Tools - Components

- Semi-finished products

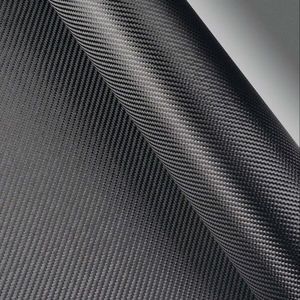

- Carbon fiber fiber

- Hexcel Corporation

Carbon fiber fiber HiTape®roving

Add to favorites

Compare this product

Characteristics

- Material

- carbon fiber

- Form

- roving

Description

HiTape® innovative high performance dry unidirectional reinforcements are designed to meet the requirements of Aircraft Primary Structures made by cost-effective Out of Autoclave (OOA) technologies such as vacuum infusion or injection.

HiTape® allows dry preforms to be manufactured in a fully automated lay-up, similar to the AFP and ATL processes widely used for UD prepregs. The tight width tolerance of HiTape® gives total control of the automated dry preform process – and it is a waste-free operation, even for complex structures, as the materials are placed exactly where required.

Using OOA vacuum infusion technology, Aircraft structures made with HiTape® demonstrate fiber volume content and mechanical properties that are very similar to parts made with the latest generation primary structure prepregs. HiTape® gives particularly high Compression After Impact (CAI) performance, which is a real breakthrough in infusion technologies with unidirectional carbon reinforcements.

Based on HexTow® carbon fibers, Hexcel supplies HiTape® with HexFlow® infusion epoxy resins for optimum mechanical performances and infusion/injection processing.

Customer evaluations have demonstrated that significant cost-savings are achievable with HiTape® and the associated vacuum infusion process. The materials allow the part design to be optimized, including function integration. The automated dry preform process is simplified, without any splicing of materials or polythene film to remove. There is no need to apply pressure to consolidate the preform and remove air as this occurs later when vacuum is applied.

VIDEO

Catalogs

Related Searches

- Roll foil

- Epoxy resin

- Industrial cloth

- Adhesive sheet

- Glass cloth

- Heat-resistant cloth

- Reinforcement technical fabric

- Roving fiber

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber

- Two-component resin

- High-performance resin

- Carbon fiber technical fabric

- Laminating resin

- Epoxy prepreg

- Maritime industry technical fabric

- Molding resin

- Chopped fiber

- Unidirectional technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.