- Materials - Tools - Components

- Semi-finished products

- Carbon fiber prepreg

- Hexcel Corporation

Tooling prepreg HexTOOL® M81carbon fiberepoxy resin

Add to favorites

Compare this product

Characteristics

- Fabric type

- carbon fiber

- Resin type

- epoxy resin

- Other characteristics

- tooling

Description

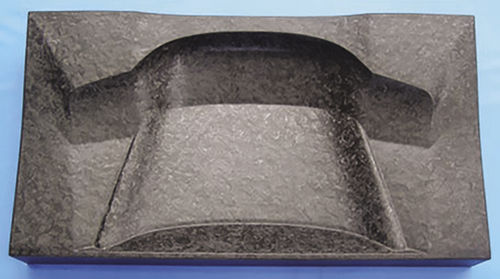

HexTool® composite tooling material combines tolerance accuracy with extreme lightness. HexTool® is Hexcel’s new patented composite tooling material that, for the first time, enables the tolerance accuracy achieved with metals to be combined with the extreme lightness of carbon fiber composites. HexTool® molds are easy to repair and are simple to modify. This new concept for lightweight, efficient large-scale tools is cost-effective compared with conventional composite tools and metal molds, especially those made from Invar®.

Since the launch of HexTool®, several leading tooling engineers have used the material confirming the benefits of the technology.

Composite tooling material for components cured at 250°F to 300°F (120°C to 150°C)

HexTool® M81 Tooling Compound is randomly layered strips of uni-directional prepreg consolidated into continuous rolled goods. It can be utilized for multi-ply quasi-isotropic hand lay-up and subsequently CNC milled to close tolerance.

HexTool® M81 has proved to be dimensionally stable with the ability to hold vacuum integrity before and after machining. Fabricated from Hexcel’s epoxy resin HexPly® M81, HexTool® M81 is ideally suited for 250°F to 300°F (120°C to 150°C) curing carbon fiber tools and can also tolerate several cure cycles at 355°F (180°C). The resulting tools are lighter and more energy efficient than tools made from steel or aluminum. They are also cost-competitive and provide tighter mold tolerances than standard composite tooling.

HexTool® means that accurate and expensive master molds are no longer necessary. Hexcel has evaluated cost-effective master mold solutions.

Catalogs

No catalogs are available for this product.

See all of Hexcel Corporation‘s catalogsRelated Searches

- Roll foil

- Epoxy resin

- Industrial cloth

- Adhesive sheet

- Glass cloth

- Heat-resistant cloth

- Reinforcement technical fabric

- Roving fiber

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber

- Two-component resin

- High-performance resin

- Carbon fiber technical fabric

- Laminating resin

- Epoxy prepreg

- Maritime industry technical fabric

- Molding resin

- Chopped fiber

- Unidirectional technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.