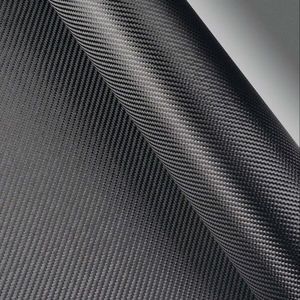

Carbon fiber technical fabric PrimeTex®reinforcement

Add to favorites

Compare this product

Characteristics

- Material

- carbon fiber

- Applications

- reinforcement

Description

PrimeTex® is a range of carbon fabrics which have been processed for a smooth, closed weave and uniform cosmetic appearance. The fiber tows are spread in both the warp and weft direction for unique aesthetic appeal. PrimeTex® fabrics are more uniform as the filaments in each tow are spread out creating a thinner and more closely woven fabric that provides better mechanicals and less porosity in a composite. It can also be used to lower the mass in a composite where lighter weight is the key characteristic.

Patented technology with fibers spread in both the warp and weft direction

PrimeTex® spreading process improves closure factor compared to conventional weaving process (depending on carbon tow and Fabric Areal Weight)

Use of higher K tow for a given Fabric Areal Weight (FAW)

Weight saving: Up to 20% at affordable cost when replacing HS3K by IM12K

Uniform weave and gap-free structure: porosity reduced / less labor for part finishing

Excellent water tightness when used in honeycomb sandwich structures

Laminate mechanical properties maintained after spreading process with reduced variability thanks to homogenous resin/fiber distribution

Typical Applications:

Aircraft and helicopter sandwich structures and thin monolithic parts

UAV/Light Aircraft market targeted by cost to weight

Automotive structures (e.g. BMW roof)

Sports equipment (e.g. skis)

Catalogs

Related Searches

- Roll foil

- Epoxy resin

- Industrial cloth

- Adhesive sheet

- Glass cloth

- Heat-resistant cloth

- Reinforcement technical fabric

- Roving fiber

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber

- Two-component resin

- High-performance resin

- Carbon fiber technical fabric

- Laminating resin

- Epoxy prepreg

- Maritime industry technical fabric

- Molding resin

- Chopped fiber

- Unidirectional technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.