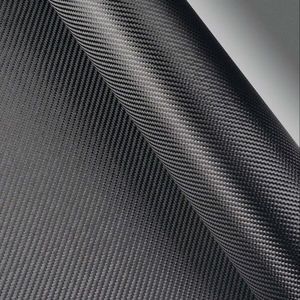

Heat-resistant technical fabric HexForce®unidirectionalfiberglassreinforcement

Add to favorites

Compare this product

Characteristics

- Type

- heat-resistant, unidirectional

- Material

- fiberglass

- Applications

- industrial, reinforcement, for electrical insulation

Description

The versatility of glass as a fiber makes it unique industrial textile material. Woven glass fibers offer an excellent combination of properties from high strength to fire resistance at a more affordable cost. Wide ranges of yarn sizes and weave patterns provide huge number of design potential allowing the end user to choose the best combination for material performance, economics and flexibility. Hexcel produces Glass Fiber Reinforcements in a wide variety of areal weights, from 48 to 1300 gsm.

Dimensional Stability: glass fiber is a dimensionally stable engineering material that does not stretch or shrink after exposure to extremely high or low temperatures. The maximum elongation for “E” glass at break is 4.8% with a 100% elastic recovery when stressed close to its point of rupture.

Moisture Resistance: glass fibers do not absorb moisture, and do not change physically or chemically when exposed to water.

High Strength: the high strength-to-weight ratio of glass fiber makes it a superior material in applications where high strength and minimum weight are required. In textile form, this strength can be unidirectional or bidirectional, allowing flexibility in design and cost.

glass fiber is an inorganic material and will not burn or support combustion. It retains approximately 25% of its initial strength at 1000°F (540°C).

Chemical Resistance: most chemicals have little or no effect on glass fiber. The inorganic glass textile fibers will not mildew, rot or deteriorate. Glass fibers are affected by hydrofluoric, hot phosphoric acids and strong alkaline substances.

Electrical Properties: glass fiber is an excellent material for electrical insulation.

Catalogs

Related Searches

- Roll foil

- Epoxy resin

- Industrial cloth

- Adhesive sheet

- Glass cloth

- Heat-resistant cloth

- Reinforcement technical fabric

- Roving fiber

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber

- Two-component resin

- High-performance resin

- Carbon fiber technical fabric

- Laminating resin

- Epoxy prepreg

- Maritime industry technical fabric

- Molding resin

- Chopped fiber

- Unidirectional technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.