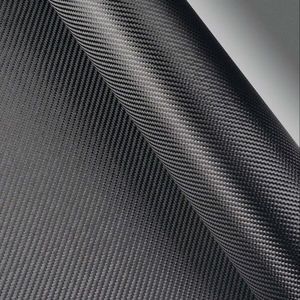

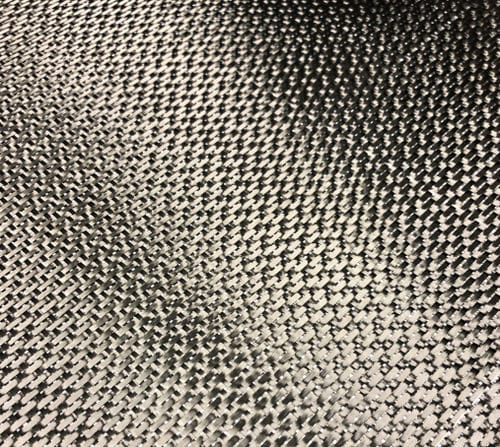

Carbon fiber technical fabric HexForce® reinforcement

Add to favorites

Compare this product

Characteristics

- Material

- carbon fiber

- Applications

- reinforcement

Description

Continuous rolls of carbon fiber fabric in which the warp and weft yarns are oriented on the bias at +/- 45°

Patented solution to optimize material usage

Hexcel has developed a patented process to manufacture continuous rolls of carbon fiber fabric in which the warp and weft yarns are oriented on the bias at +/- 45° in standard plain or crow foot satin weaves.

Benefits

Reduced prepreg waste (up to 60% savings)

Prepregged fabrics can be slit to an optimum width for automated manufacturing

Kitting waste from cutting of standard 0/90° to +/- 45° is eliminated

Reduced labor

Pattern cutting and lay-up is simplified

Increased design allowables as the warp and fill will have the same properties due to an equal amount of crimp (unlike standard 0/90 fabrics)

Elimination of fabric or prepreg splices in parts

This continuous fabric provides constant thickness along the length of the part by eliminating seams

Typical Applications

Ideal for high aspect ratio parts that need bias reinforcement:

Ribs, stringers, spars

Helicopter blades

Engine nacelles

Secondary structures

Barrel sections of aircraft

Product Range

Currently available for 193 to 285 3K HS and from 193 to 285 6K IM

HexForce® PX (+/-45° plain weave)

HexForce® CSX (+/-45° crow foot satin weave)

Produced with high strength (HexTow® AS4) and intermediate modulus (HexTow® IM7) fibers. Minimum master width available: 50” and 60”. Ideal for prepreg and RTM processing.

Catalogs

Related Searches

- Roll foil

- Epoxy resin

- Industrial cloth

- Adhesive sheet

- Glass cloth

- Heat-resistant cloth

- Reinforcement technical fabric

- Roving fiber

- Carbon technical fabric

- Cloth for the automotive industry

- Carbon fiber

- Two-component resin

- High-performance resin

- Carbon fiber technical fabric

- Laminating resin

- Epoxy prepreg

- Maritime industry technical fabric

- Molding resin

- Chopped fiber

- Unidirectional technical fabric

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.