- Machine-tools

- Machining Center

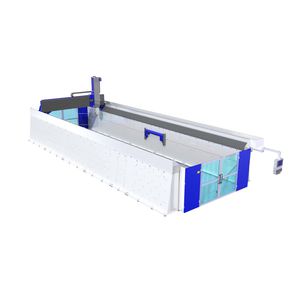

- 5-axis CNC milling machine

- HG GRIMME SysTech GmbH

5-axis CNC milling machine G-S-F/Basisverticalfixed-bedfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- fixed-bed

- Machined material

- for aluminum, for PVC, for composites

- Associated functions

- drilling

- Applications

- for the aeronautical industry, for the automobile industry, for aeronautics, for the mold industry, for model making, for the plastics industry, CAD/CAM, for profiles, for PVC window profiles

- Other characteristics

- compact, high-speed, high-performance, rigid, precision, high-precision, high-productivity, high-speed, HSC, with pneumatic clamping, high-power, medium-sized, with automatic tool changer

- X travel

Min.: 2,600 mm

(102.36 in)Max.: 3,600 mm

(141.73 in)- Y travel

Min.: 1,600 mm

(62.99 in)Max.: 2,200 mm

(86.61 in)- Z travel

910 mm

(35.83 in)- Rotational speed

Min.: 24,000 rpm

(150,796 rad.min-1)Max.: 40,000 rpm

(251,327 rad.min-1)- Power

Min.: 3 kW

(4.08 hp)Max.: 9 kW

(12.24 hp)- Table load capacity

500 kg

(1,102 lb)

Description

CNC 5-axis milling machine G-S-F/B

The CNC milling machine Basis in gantry design is the most popular entry-level model for milling plastics and composites as well as model making materials.

The CNC machining center has high feed rates and due to the torsion-resistant steel construction in gantry design, the CNC machine achieves excellent milling results. For optimal safety, all drives and guides of the CNC machining center are in the protected segment or above the working area.

Of course, this CNC milling machine also offers over 365 options from our standard to meet all individual requirements. Thus, the installation of a vacuum grid table, as well as the equipment with a partition wall for tandem operation and many other options, can be realized easily and cost-effectively.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HG GRIMME SysTech GmbH‘s catalogsOther HG GRIMME SysTech GmbH products

5-axis CNC milling machine | Gantry | CNC machining center | HG GRIMME SysTech

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- High-performance CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine with pallet changer

- CNC milling machine for the mold industry

- High-productivity CNC milling machine

- Composite CNC milling machine

- CNC milling machine with moving table

- CNC milling machine for the automobile industry

- Horizontal CNC milling machine

- CNC milling machine with rotary table

- Fixed-bed CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.