- Machine-tools

- Machining Center

- 5-axis CNC milling machine

- HG GRIMME SysTech GmbH

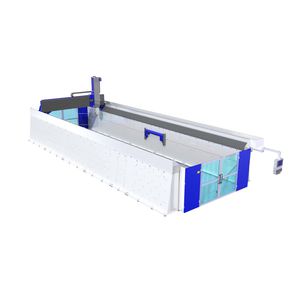

Composite CNC milling machine G-DT-F (12-10) SB5-axishorizontalwith rotary table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Structure

- with rotary table, inclined bed

- Machined material

- for composites

- Associated functions

- drilling

- Applications

- for the aeronautical industry, for the automobile industry, for aeronautics, for the mold industry, for the plastics industry, for model making, CAD/CAM, for profiles, for PVC window profiles

- Other characteristics

- high-speed, compact, high-performance, precision, high-precision, high-productivity, HSC, high-power, with pneumatic clamping, medium-sized, with automatic tool changer

- X travel

Max.: 3,900 mm

(153.54 in)Min.: 1,800 mm

(70.87 in)- Y travel

Max.: 2,400 mm

(94.49 in)Min.: 1,600 mm

(62.99 in)- Z travel

815 mm

(32.09 in)- Rotational speed

32,000 rpm

(201,062 rad.min-1)- Power

9 kW

(12.24 hp)- Table load capacity

Max.: 1,000 kg

(2,205 lb)Min.: 500 kg

(1,102 lb)

Description

Maximum Production Capacity in a Small Space. You can carry out technically demanding work on 3D solids perfectly and especially efficiently with the five-axis technology. This kind of production precision is a convincing argument in the automotive supply, aircraft and aerospace industries as well as in yacht construction and the sanitary fittings industry. Maximum production capacity thanks to vertical rotary tandem table. Saving of space due to reduced dimensions. Compact 5-axis milling head for the high-precision three dimensional machining of various materials. Ergonomic placing and removal of the work pieces from outside the machine area at the loading table at the front, with loading angle 170°. Time is saved when cleaning the machine through gratings and chip collection tubs in the interior of the machine. Protection against dust, chips and noise due to the safety concept of all-round enclosure (cabin, laser scanner).

- Max. rotation range – C 455°

- Max. swivel range – A 362°

- 2 Machine tables with ergonomic loading angle 170°

- Each table side 1,200 x 1,000 mm

- Table rotation ± 180°; 3.0 sec

- Loading weight each side max. 300 kg

- Table accuracy ± 0.12 mm

- Max. acceleration each linear axe 3,500 mm/sec²

- Max. speed in X/Y 60,000 mm/min

- Max. speed in Z 35,000 mm/min

- Max. speed in C 15,000°/min

- Max. speed in A 9,000°/min

- Positioning accuracy ± 0.070 mm

- Repeatability ± 0.050 mm

- High-frequency milling spindle DUO Classic 100, IMT

- Tool holder 2 x HSK-C 40, max. 16 mm

- CNC control Siemens Sinumerik 840D SL Operate or NUM Flexium

- Dimensions incl. safety cabin, appr. 5,080 x 3,670 x 3,240 mm (l x w x h)

- Machine weight appr. 6,500 kg

VIDEO

Other HG GRIMME SysTech GmbH products

5-axis CNC milling machine | Gantry | CNC machining center | HG GRIMME SysTech

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- High-performance CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine with pallet changer

- CNC milling machine for the mold industry

- High-productivity CNC milling machine

- Composite CNC milling machine

- CNC milling machine with moving table

- CNC milling machine for the automobile industry

- Horizontal CNC milling machine

- CNC milling machine with rotary table

- Fixed-bed CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.