- Production Machines

- Cutting Machine

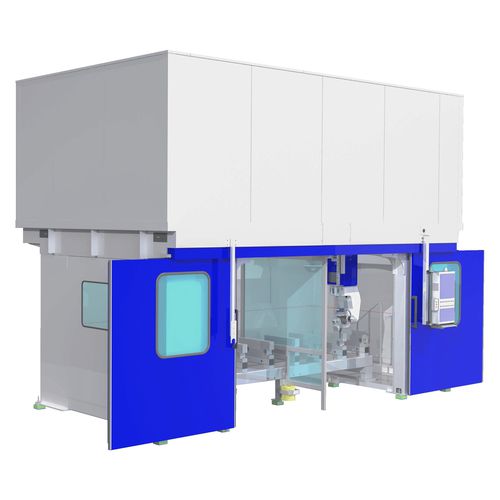

- Ultrasonic cutting machine

- HG GRIMME SysTech GmbH

Scoring cutting machine G-S-Kknifeultrasonicfor rubber

Add to favorites

Compare this product

Characteristics

- Technology

- knife, ultrasonic

- Material

- for rubber, for foam, for PVC, for PMMA, for leather

- Product handled

- profile, for PVC profiles, for foam panels, contour, for flexible PU foam blocks, multi-ply fabric, single-ply fabric, strip fabric

- Control type

- CNC

- Associated function

- contour, scoring

- Applications

- for industrial applications, for the automotive industry, for aeronautical applications

- Configuration

- compact, single-head, 6-axis

- Other characteristics

- automatic, high-precision, with CCD camera, high-speed, precision, high-performance, CE, high-power, with exchange table, for mass production, large capacity, multi-axis, for technical textiles, for plastic film, programmable, for thin materials, 3D, for heavy-duty applications, custom-made

- X travel

Min.: 2,600 mm

(102.36 in)Max.: 3,600 mm

(141.73 in)- Y travel

1,500 mm

(59.06 in)

Description

The 6-axis technology allows complex components to be machined intelligently and with particular accuracy. The high production accuracy is a winning factor in industry sectors such as the automotive supply industry. Application possibilities are for example synthetic and leather airbags. 6-axis technology in gantry design. Tandem operation possible by installing a dividing wall. Big variety of individual equipment possibilities such as fixed blade or ultrasonic cutting device. Highest accuracy for production of weak. Clean cuts, exact solid contours, accuracy in absolute values up to 30 μm of produced predetermined breaking lines in airbag wall weakening. Excellent acceleration and feed values. Documentation of process parameters. High-precision linear distance measurement systems (glass scales), optional. Safety cabin (opt.: air conditioned). In-house design and production of fixtures.

- Rotation axis C 540°

- Swivelling axis A 365°

- Rapid traverse linear axes X/Y 60 m/min (110 m/min with linear drive opt.)

- Rapid traverse linear axis Z 30 m/min

- Rapid traverse rotary axes A/C 9,000°/min / 12,000°/min (15,000°/min / 25,000°/min with linear drive opt.)

- Positioning accuracy ± 0.05 mm (± 0.03 mm with glass scale opt.)

- Repeatability ± 0.05 mm (± 0.03 mm with glass scale opt.)

- Cutting device blade clamping for cutting blade with additional CNC axis for blade tracking

- Ultrasonic cutting device ultrasonic cutting blade with additional CNC axis for blade tracking, depending on the application, with 20 kHz or 35 kHz ultrasonic generator

- CNC control Siemens Sinumerik 840D/SL Operate

- Machine weight approx. 8,000 kg

VIDEO

Catalogs

Related Searches

- Cutting system

- CNC cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- Compact cutting system

- High-power cutting machine

- Profile cutting center

- Cutting machine for aeronautical applications

- 3-axis cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.