- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

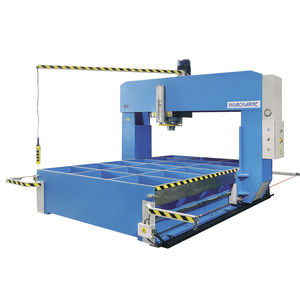

Hydraulic press MV-800tryouttest4-column

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- tryout, test

- Structure

- 4-column

- Other characteristics

- electronic

- Applications

- for tools

- Force

7,971.2 kN

- Opening

1,000 mm

(39 in)

Description

This MV-800 HIDROGARNE hydraulic press, with four stanchions, 800 tons of power and synchro-electronic system, is specially designed and manufactured for the adjustment and testing of molds or dies

As all our M series hydraulic press, this is esigned with four cylindrical columns for increased accuracy and capacity.

Structure and tables

- Structure designed to support 600 TN of force concentrated in 1/ 3 part of its surface.

- Chrome-plated and grounded columns of 250 mm with bellows of protection.

- Lower table with “T” grooves arranged on the table according to the indications of the user.

- Upper table with “T” grooves and anti-fall safety system.

CYLINDER AND HYDRAULIC UNIT

One speed hydraulic unit with automatic disconnection of the pre-filling speed and independent operation, provided with decompression system and pre-filling valves with proportional pressure valve and with digital potentiometers on the top table for the control of the displacement and synchronized electronic system for compensation of off-centre efforts

ELECTRIC INSTALLATION AND SAFETY

Electric installation with selector for operation of the main cylinder to 1 or 2 speeds.

Hydraulic press with one manual cycle and one automatic cycle (activated by selector with proof key):

The manual cycle allows the execution of all the movements (step by step) of the press on slow speed.

The automatic cycle allows the press to carry out a complete production sequence.

Electrical safety system for the anti-fall system of the top table.

Bottom table with hydraulic extraction and stop by physical ends.

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.