- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

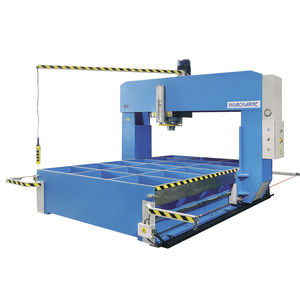

Manual press RM-80Ehydraulicstampingdownstroke

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, manual

- Function

- stamping

- Structure

- downstroke

- Control

- automatic

- Force

20 tf, 80 tf

- Opening

250 mm

(10 in)- Stroke

250 mm

(9.843 in)- Table width

600 mm, 700 mm

(24 in, 28 in)- Table length

450 mm, 500 mm

(18 in, 20 in)- Max. pressure

256 bar

(3,713 psi)- Working speed

12 mm/s

- Return speed

150 mm/s

- Approaching speed

120 mm/s

- Weight

3,500 kg

(7,716 lb)- Overall height

2,650 mm

(104 in)

Description

As all our R series hydraulic presses, this is equipped with a mechanized upper CK-42 stainless steel table to ensure perfect parallelism and precision.

STRUCTURE AND TABLES

Sturdy construction with closed sides.

Upper table with four guides Ø 50 mm with bimetallic antifriction sockets of maintenance free.

Upper and lower tables with machined ” T” slots of M16 x 18

Hydraulic cushion placed at the lower table with 12 candles Ø 30

Hydraulic ejector of 2 tons and a stroke of 25 mm placed at the upper table

CYLINDER AND HYDRAULIC UNIT

2 side cylinders for approach and quick return.

Hydraulic unit located on the top rear.

DENISON-PARKER pump.

HITOS pressure and manoeuvre electro valves

Gauges tonnes.

Front pressure regulator

Pressure regulator for the cushion.

Air-oil cooler.

ELECTRIC INSTALLATION AND SAFETY

Electric panel located on the right side.

Limit switches located on the Left Side

Three adjustable strokes ending for the upper table, two to adjust the table stroke and one to change the speed.

Two stroke endings for the cushion, 2 limit switches in the pad, to forward and reverse.

Pressure switch for end of cycle.

Selector 1 or 2 speeds.

Selector for manual or automatic cycle.

Selector for the annulment of the hydraulic cushion.

Selector for the annulment of the hydraulic ejector.

Security module for bimanual and emergency stop.

Reset button.

Emergency stop type “Z” with latching

Back protections with security opening

It meets and satisfies all the essential health and safety requirements in accordance with the EC standard.

Catalogs

No catalogs are available for this product.

See all of HIDROGARNE‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.