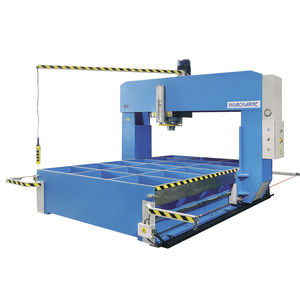

Hydraulic press MV-250 Emotorizeddeep drawingwelding

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, motorized

- Function

- deep drawing, welding

- Structure

- 4-column

- Control

- CNC

- Applications

- process

- Force

250 tf

- Opening

500 mm

(20 in)- Stroke

500 mm

(19.685 in)- Table width

1,150 mm

(45 in)- Table length

2,500 mm

(98 in)- Max. pressure

260 bar

(3,771 psi)- Working speed

7 mm/s

- Return speed

105 mm/s

- Approaching speed

80 mm/s

- Weight

15,000 kg

(33,069 lb)- Overall height

3,650 mm

(144 in)

Description

As all our M series hydraulic press, this press is equipped with a mechanized lower and upper C45E stainless steel table with two DIN-650 grooves.

STRUCTURE AND TABLES

This customized hydraulic press consists of three electro welded sections made solely of S355JR steel.

It’s stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision.

Calculated and designed by finite software.

With all this, we always guarantee our high precision and quality standards.

It’s equipped with a mechanized lower and upper C45E stainless steel table with two DIN-650 grooves.

We ensure a minimal friction in the vertical displacement of the upper table by installing alloy bronze bushings with graphite filler and a perfect parallelism by four cylindrical columns chromed, rectified and made of C45E steel.

The upper table ensures perfect alignment by means of four cylindrical lateral rails with anti-friction bimetallic caps which require no maintenance.

The lower table accommodates a hydraulic cushion of 50 tons with a useful area of 950 mm x 750 mm and three frontal arms to support the matrix on the outside of the press.

It has a NC SIEMENS KP-400 to control adjustments to the position of the upper table, changes of the speeds and cushion

It has a PLC SIEMENS S-7 that allows to program 99 memories.

CYLINDER AND HYDRAULIC UNIT

The cylinder is single acting with a lapping liner, chrome plunger and maintenance-free anti wear guides.

The hydraulic group is located entirely on top of the hydraulic press.

The hydraulic group includes Denison silent hydraulic pump and air-oil cooler.

It includes:

decompression system,

pressure solenoid valves,

VIDEO

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.