- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

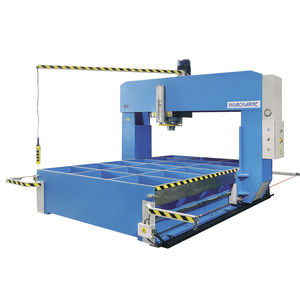

Hydraulic press MV-1000 Evulcanizing4-column

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- vulcanizing

- Structure

- 4-column

- Force

1,000 tf

- Opening

1,500 mm

(59 in)- Stroke

1,500 mm

(59.055 in)- Table width

1,500 mm

(59 in)- Table length

1,500 mm

(59 in)- Max. pressure

300 bar

(4,351 psi)- Working speed

3 mm/s

- Return speed

110 mm/s

- Approaching speed

90 mm/s

- Hydraulic pump power

30 kW

- Weight

60,000 kg

(132,277 lb)

Description

Structure of four cylindrical chrome columns of diameter 250mm, made exclusively of C45E steel.

Central table with “T” grooves, guided by the 4 columns and bronze-graphite bushings.

Bottom table with “T” grooves and front hydraulic extraction with capacity to move loads until 25 TN.

The useful dimensions of the tables are 1500x1500mm.

The tables have incorporated two heated plates that can reach 250ºC of temperature

they are controlled by a thermal system TL 42-1/4 that allows to make a register of pressure, temperature, visualization and storage of data.

The precision of the thermal plates is +-5%.

They include a cooling circuit.

It incorporates a NC SIEMENS S-7/1200 KP-400, to regulate the travel of the table, the working pressure, the hydraulic peripherals, programming the time of pressing and changes of speed.

CYLINDERS AND HYDRAULIC UNIT

Two lateral cylinders for a fast approaching and return of the central table.

Hydraulic unit is two-speed motorized with fast speed automatic shut-off.

REXROHT pressure and manoeuvre valves.

DENISON-PARKER double Vane Pump for high and low pressure.

It incorporates hydraulic connections for auxiliary peripherals and air-oil cooling system.

The hydraulic group is located at the top of the press and to facilitate its access it has been installed a passable walkway.

ELECTRIC INSTALLATION AND SAFETY

The control panel incorporates a selector that allows to choose the type of work that we want to perform in manual or automatic cycle.

It also incorporates a selector to select the operation in speed of fast approaching, slow speed of working and adjustment of the tools.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.