- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

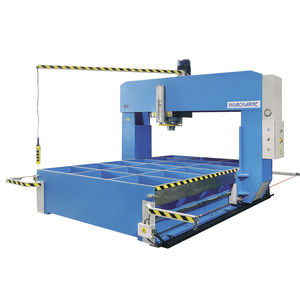

Hydraulic press CM-150EmotorizedstampingC-frame

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, motorized

- Function

- stamping

- Structure

- C-frame

- Control

- automatic, CNC

- Other characteristics

- digital, cold

- Force

150 tf

- Opening

250 mm

(10 in)- Stroke

250 mm

(9.843 in)- Table width

700 mm, 900 mm

(28 in, 35 in)- Table length

450 mm, 650 mm

(18 in, 26 in)- Max. pressure

320 bar

(4,641 psi)- Working speed

6 mm/s

- Return speed

110 mm/s

- Approaching speed

160 mm/s

- Weight

4,150 kg

(9,149 lb)- Overall length

955 mm

(38 in)- Overall width

1,600 mm

(63 in)- Overall height

2,900 mm

(114 in)

Description

Customized manufacture of the HIDROGARNE C-frame motorized hydraulic press mod. CM-150 E that has been designed and manufactured to comply with all requirements and indications of our customer to carry out works of average production of cold stamping.

As all our CM series hydraulic pressess this is equipped with a mechanized lower and upper CK-42 stainless steel table to ensure a perfect alignment.

Structure and tables

- Made with a C frame structure electro-welded with ST-52-3 and machined after welding.

- CK-42 lower table with “T” machined grooves.

- CK-42 upper table with “T” machined grooves.

CYLINDER AND HYDRAULIC UNIT

Single action main cylinder with a lapping liner, chrome plunger and maintenance-free anti wear guides.

2 lateral cylinders to fast approach speed.

A two-speed motorized hydraulic unit with automatic high speed deactivation

DENISON-PARKER silent hydraulic pump.

Cooler with Air-oil.

Pressure and manoeuvre electro valves REXROTH

EQUIBERMA Prefilling valves.

OPERATED, ELECTRIC INSTALLATION AND SAFETY

Operated by two electric pedals with low electric voltage.

CNC digital con válvulas proporcionales para la regulación de:

Maximum up, maximum down and speed selector

Programmable working pressure.

Speed selector.

Manual, semiautomatic or automatic cycle selector

SCHNEIDER security module.

Emergency stop “Z”.

Side guards with security opening and frontal light barriers with level IV.

IP-55 electric frame

Se suministran con manómetro de glicerina con lectura en toneladas, aceite hidráulico y manual de instrucciones.

It meets and satisfies all the essential health and safety requirements in accordance with the EC standard.

Catalogs

No catalogs are available for this product.

See all of HIDROGARNE‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.