- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

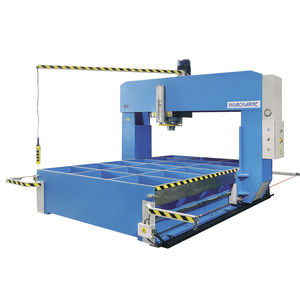

Manual press FL serieshydraulicmotorizedwelding

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, manual, motorized

- Function

- welding

- Control

- automatic

- Other characteristics

- fixed

- Applications

- process

- Force

100 tf, 150 tf, 220 tf, 300 tf

- Max. pressure

320 bar

(4,641 psi)- Working speed

2 mm/s, 2.2 mm/s, 3.1 mm/s

- Return speed

14.4 mm/s, 14.7 mm/s, 15.4 mm/s, 16.2 mm/s

- Approaching speed

9 mm/s, 9.2 mm/s, 9.9 mm/s

- Hydraulic pump power

4 kW, 5.5 kW, 7.5 kW

- Weight

2,170 kg, 2,680 kg, 3,720 kg, 4,390 kg

(4,784 lb, 5,908 lb, 8,201 lb, 9,678 lb)- Overall height

2,375 mm, 2,470 mm, 2,835 mm, 2,925 mm

(94 in, 97 in, 112 in, 115 in)

Description

F-series hydraulic presses consist of an electro welded structure made solely of S355JR steel. They are machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite software. With all this, we always guarantee our high precision and quality standards.

The equipment features a fixed bed to ensure greater robustness.

It includes two flat blocks.

Three different models are available:

FDM models: equipped with a fixed headstock and several headstocks may be installed on the same machine

FLM models: equipped with a headstock of lateral displacement by wheels, featuring a manual locking system.

FLV models: equipped with a headstock of lateral displacement by steering wheel and a rack transmission system, featuring a manual locking system.

CYLINDER AND HYDRAULIC UNIT

The cylinder is double acting with a lapping liner, chrome plunger and maintenance-free anti wear guides, it’s fitted with a removable and interchangeable hold-down plate to avoid the deterioration of the plunger and machined at the end to adapt tools. Anti-turning of the cylinder with a squared front and stroke endings come as standard which enable us to conveniently regulate the cylinder stroke.

They allow the installation of multiple headstocks in one machine.

A two-speed motorized hydraulic unit with automatic high speed deactivation. It’s equipped with a cylinder decompression valve.

They are supplied with a glycerin gauge with reading in tonnes.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.