- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

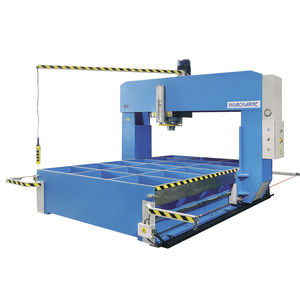

Manual press FDV-330 Ehydraulicformingwelding

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, manual

- Function

- forming, die-cutting, welding

- Control

- automatic, NC

- Other characteristics

- fixed, digital

- Applications

- process

- Force

330 tf

- Stroke

450 mm

(17.717 in)- Max. pressure

290 bar

(4,206 psi)- Working speed

5.8 mm/s

- Return speed

75 mm/s

- Approaching speed

75 mm/s

- Hydraulic pump power

22 kW

- Weight

23,500 kg

(51,809 lb)- Overall height

3,225 mm

(127 in)

Description

As all our F series hydraulic press, they are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision.

STRUCTURE AND TABLES

Electro-welded structure exclusively manufactured in S355JR steel.

It is mechanized at the end of the welding process.

Calculated and designed with finite elements software and with 4 level structural coefficient. Whit this, we always guarantee our high standards of precision and quality.

It has fixed bed structure with open sides.

Mechanized top table of 3.100 x 1400 x 145 mm with 4 lateral guides Ø 80 and 6 “T” grooves.

Mechanized lower table of 3.100 x 1400 x 120 mm with 6 “T” grooves.

CYLINDER AND HYDRAULIC UNIT

Three single-acting cylinders of 110 Tons each one, with pre-filling valve, lapping liner, chrome plunger and maintenance-free anti wear guides.

Two lateral double-acting guides for fast approach and quick return.

Hydraulic group located in the upper rear.

Incorporates a piston pump with constant power.

It has automatic disconnection of fast speed, decompression valve of the cylinder and manometer in tons.

It incorporates a circuit of independent cooling with oil air converter.

ELECTRIC INSTALLATION AND SAFETY

The control panel incorporates a Siemens NC with Siemens KP-400 screen and a PLC Siemens S-7/1200.

With decimal readout, and digital positioning that allows programming the desired type of work in manual or automatic position,

to regulate the working pressure,

time of pressing and changes of speeds.

It allows the programming of 99 folders with different cycles of work. The PLC has been programmed to synchronize the press with a robotic arm.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.