- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

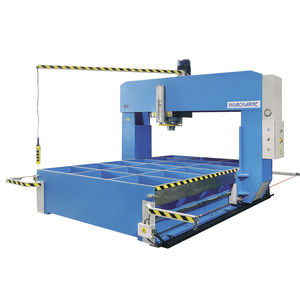

Hydraulic press RV-2000Eweldingupstrokepanel

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- welding

- Structure

- upstroke

- Applications

- process, panel

- Force

2,000 tf

- Stroke

220 mm

(8.661 in)- Working speed

0.7 mm/s

- Return speed

28 mm/s

- Approaching speed

19 mm/s

- Hydraulic pump power

15 kW

- Weight

50,000 kg

(110,231 lb)- Overall length

1,300 mm

(51 in)- Overall width

2,300 mm

(91 in)- Overall height

3,320 mm

(131 in)

Description

As all our R series hydraulic press, they are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision.

STRUCTURE AND TABLES

This press is manufactured with a special structure of rigid arch by segments, calculated and designed by finite software with level 5 structural resistance.

With all of this, we can guarantee our high precision and quality standards.

Provided with a bottom circular table of 550 mm diameter and 8 cylindrical guides.

The press has a removable plate by hydraulic acting, for the works of feeding and removable of the pieces.

CYLINDER AND HYDRAULIC UNIT

The main cylinder of simple effect by upstroke acting, equipped with a pre-filling valve and 4 auxiliary cylinders for the advance and quick return of the table.

The hydraulic unit of 15Kw with variable flow pump and constant power, allows make a complete cycle every 2 minutes.

ELECTRIC INSTALLATION AND SAFETY

The electric panel incorporates a SIEMENS PLC with PROFINET configuration. Programming by means a KT-700 display.

Electrical and hydraulic manoeuvres are redundant and self-controlled.

They incorporate and additional safety block and self-control devices for manoeuvre and safety.

It includes the verification and certification of the correct operation and the safety distance for the photocells.

Operation is carried out by low voltage electric pedals.

Safety is guaranteed by the use of level IV photoelectrical sensors located at the front and back side of the press.

The press meets and satisfies all the essential health and safety requirements in accordance with the CE rules.

Catalogs

No catalogs are available for this product.

See all of HIDROGARNE‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.