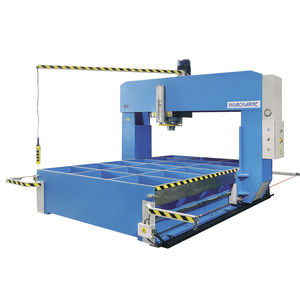

Hydraulic press RM seriesmotorizeddeep drawingcutting

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, motorized

- Function

- stamping, deep drawing, cutting

- Structure

- downstroke

- Control

- automatic

- Other characteristics

- double-action

- Applications

- for production

- Force

Max.: 500 tf

Min.: 80 tf

- Opening

250 mm, 300 mm, 500 mm

(10 in, 12 in, 20 in)- Stroke

250 mm, 300 mm, 500 mm

(9.843 in, 11.811 in, 19.685 in)- Table width

Max.: 1,000 mm

(39 in)Min.: 600 mm

(24 in)- Table length

Max.: 850 mm

(33 in)Min.: 450 mm

(18 in)- Max. pressure

320 bar

(4,641 psi)- Working speed

Max.: 6.2 mm/s

Min.: 2.4 mm/s

- Return speed

17 mm/s, 19 mm/s, 30 mm/s, 36 mm/s, 48 mm/s

- Approaching speed

Max.: 30 mm/s

Min.: 10 mm/s

- Hydraulic pump power

5.5 kW, 7.5 kW, 11 kW, 15 kW

- Weight

Max.: 12,150 kg

(26,786 lb)Min.: 2,080 kg

(4,586 lb)- Overall height

Max.: 3,610 mm

(142 in)Min.: 2,500 mm

(98 in)

Description

Specifically designed to perform work involving deep-drawing, stamping, die-cutting, forming, etc.

The latest generation R series hydraulic presses now feature a wide range of uses including the possibility of incorporating these machines in automatic production lines.

This series works with hydraulic pressure lower than 320 bar to ensure the greater durability of the hydraulic system as a whole.

STRUCTURE AND TABLES

R-series deep drawing and forming presses consist of an electro welded structure made solely of S355JR steel. They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision. Calculated and designed by finite software. With all this, we always guarantee our high precision and quality standards.

These models are equipped with a mechanized lower and upper C45E steel table with DIN-650 grooves. The upper table ensures perfect alignment by means of four cylindrical lateral guides with maintenance-free anti-friction bimetallic caps.

Adjustments to the position of the upper table and changes in speed are controlled from a three-way side panel.

CYLINDER AND HYDRAULIC UNIT

The cylinder is double acting with a chrome plunger and maintenance-free anti wear guides.

A two-speed motorized hydraulic unit with automatic high speed deactivation. It’s equipped with a cylinder decompression valve. A pressure regulator placed at the front part comes as standard which allows the regulation of the most appropriate pressure for each kind of pressing.

They are supplied with a glycerin gauge with reading in tonnes.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.