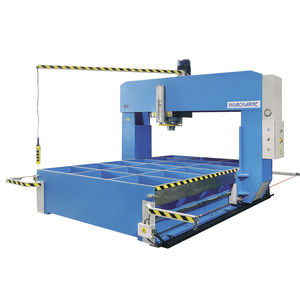

Hydraulic press D seriesstraighteningdeep drawingswaging

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- straightening, deep drawing, swaging, punching, bending

- Structure

- downstroke, double-column

- Other characteristics

- double-action, shop

- Force

100 tf, 150 tf, 220 tf, 300 tf

- Opening

250 mm, 300 mm

(10 in, 12 in)- Stroke

250 mm, 300 mm

(9.843 in, 11.811 in)- Max. pressure

320 bar

(4,641 psi)- Working speed

2 mm/s, 2.2 mm/s, 3.1 mm/s

- Return speed

14.4 mm/s, 14.7 mm/s, 15.4 mm/s, 16.2 mm/s

- Approaching speed

9 mm/s, 9.2 mm/s, 9.9 mm/s

- Hydraulic pump power

3.1 kW, 5.5 kW, 7.5 kW

- Weight

1,170 kg, 1,875 kg, 3,360 kg, 3,890 kg

(2,579 lb, 4,134 lb, 7,408 lb, 8,576 lb)- Overall height

2,465 mm, 2,705 mm, 3,165 mm, 3,300 mm

(97 in, 106 in, 125 in, 130 in)

Description

Specifically designed to perform work involving fretwork, deep-drawing, punching, bending, straightening, etc.

Consist of an electro welded structure made solely of SR355JR steel. They are mechanized at the end of the structural welding process.

Mobile table which enables the equipment to be positioned at different heights. The equipment is secured by means of two center pins located in the center of the table. The raising and lowering system operates by chains driven by means of a hoist equipped with a gear reducer. it incorporates lateral wheels for guiding. The gear system is located in the rear outer part in order to leave the entire inner part of the table free.

• DM models: The table is raised using a manually operated gear system.

• DV models: The table is raised using a motor and a gear reducer.

The cylinder is double acting with chrome plunger and maintenance-free anti wear guides, it’s fitted with a removable and interchangeable hold-down plate to avoid the deterioration of the plunger and machined at the end to adapt tools.

Anti-turning of the cylinder with a millimeter frontal and stroke endings come as standard which enable us to conveniently regulate the cylinder stroke.

A two-speed motorized hydraulic unit with automatic high speed deactivation. It’s equipped with a cylinder decompression valve.

It works with hydraulic pressure lower than 320 bar

Glycerin gauge with reading in tonnes.

The control panel features a switch enabling the user to select the desired type of work in a manual or semi-automatic position and a switch to select either the fast speed or slow speed.

Operation is carried out by low voltage electric pedals.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.